Editors’ Picks

Found in Robotics News & Content, with a score of 8.91

…automated piece-picking systems to address challenges including high SKU inventories, complex packaging, and fragile items. The company said its systems support goods-to-robot (G2R) use cases. It claimed that its Hypercare support covers everything from concept exploration to onsite installation. “Our AI-driven SightWorks vision software and associated technologies provide the foundation for all of our warehouse solutions,” said Derik Pridmore, CEO of OSARO. “[They are] available to strategic partners, including FANUC’s ASI network of robot integrators, to build the custom applications and control technologies required to identify, pick, and place any object.” “By collaborating on engineering and business development, FANUC and…

Found in Robotics News & Content, with a score of 8.80

…we look at the department store leader’s focus on inventory productivity. Can a 165-year-old department store chain evolve to meet today’s retail shopper and compete with fast fashion, off-price, and pure e-tailers? And, if so, what is the role of supply chain in that transformation? Those are questions that Macy’s Inc., which had annual net sales of more than $24 billion in fiscal year 2022, began to answer before COVID-19. That’s when it launched the reinvention of the supply chain that largely supports the Macy’s brands. One metric for the company is the “inventory productivity,” according to Dennis Mullahy, chief…

Found in Robotics News & Content, with a score of 8.76

…rate hovering at record lows and warehouses bloated with inventory pulled in from China during 2018 to get ahead of impending tariffs, have emerged creating an even more demanding environment. For these reasons, proper inventory management—accompanied by the ability to move inventory throughout the supply chain at a high velocity and lower cost—has become a must-have in today’s business climate. Experts agree that as autonomous robot hardware and software continues to improve over the next 10 years, robots can provide a competitive advantage for companies. Through improvements in sensors, dexterity, artificial intelligence, and trainability. However, the day when “robots take…

Found in Robotics News & Content, with a score of 8.74

…integrated e-commerce platform and modularized intelligent warehouse with real-time inventory tracking. The company was looking to streamline order fulfillment operations at its logistics facility in Toronto, Canada. HWArobotics describes its goods-to-person AS/RS installed at Darwynn’s facility as a multi-level shuttle system with 24 carts, 6 cart elevators, and 10,368 storage locations. During the first phase of Darwynn’s project, storage was configured as 3 double-deep aisles with 8 levels enabling parallel operation of multiple shuttle carts. The system included picking stations and WCS systems. AS/RS system’s inventory capacity totals 200,000 items Darwynn was looking to meet the demands of its business…

Found in Robotics White Papers & Archives, with a score of 8.60

…provide WCS performance, while many WCS offerings now offer inventory management and other functionality in an effort to occupy the role of a WMS. Then there’s the latest entrant – WES, which aims to be a true hybrid of WMS and WCS. But what does that really mean for operations looking to make the right investment? What if there was a way to simplify the warehouse software discussion, breaking out of the W_S acronyms with substantive discussion of what the software must do and how it must perform? This white paper discusses the established software paradigm for warehouses and distribution…

Found in Robotics News & Content, with a score of 8.51

…Corp. and Tennant Co. announced that they will demonstrate Inventory Scan, a new data-capture accessory for Tennant's autonomous floor scrubbers, at Interclean in Amsterdam next week. “This new product marks the beginning of realizing the next phase in our company's vision and continued growth in Europe as well as the U.S.,” stated Dr. Eugene Izhikevich, CEO of Brain Corp. “We are actively taking BrainOS-powered robots from primarily task-oriented machines to in-store data-acquisition platforms. This delivers critical insights, and this will add significant ROI [return on investment] for European retailers as we continue to expand our activity in Europe and beyond.”…

Found in Robotics News & Content, with a score of 8.51

…waste hours each week looking for trailers. Our trailer inventory solution brings much-needed visibility and insight to maximize productivity and yard throughput.” “Outrider’s automated trailer inventory uses a full stack of technologies to dynamically confirm trailer and container locations in distribution yards,” said Luciano Spinello, senior director of autonomy and artificial intelligence at Outrider. “As our autonomous vehicles operate in yards, they use computer vision to capture and relay trailer data into our state-of-the-art deep learning software models. Advanced algorithms process the data, turning it into valuable information for customers to streamline their yard operations.” Trailer inventory is enabled, managed,…

Found in Robotics News & Content, with a score of 8.50

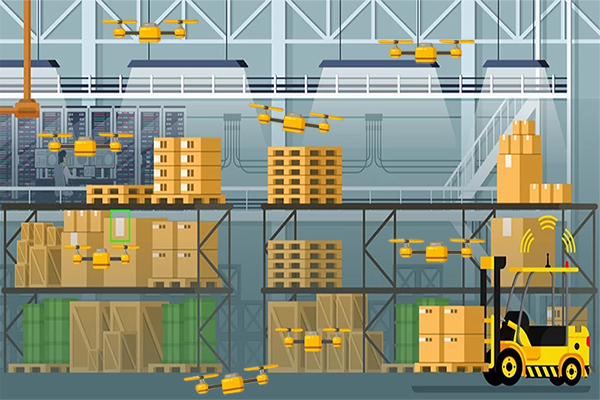

…or yard; autonomous drones can perform mundane and repetitive inventory management tasks (as well as tasks that are dangerous for humans, such as flying up to view inventory on high shelves); and robots can lift shelving units from densely-packed storage areas and then transport those goods to a picking station. Read: Are Robots Going to Replace People in the Warehouse? Today’s customers expect same-day and next-day delivery guarantees. When they don’t get what they want, they can find another source with just a couple of screen taps or mouse clicks. For this reason, good inventory management - accompanied by the…

Found in Robotics News & Content, with a score of 8.04

…industry leader in autonomous drones or aerial robots. PINC’s inventory robotics solution allows companies to apply autonomous drone technology, coupled with artificial intelligence, advanced computer vision, RFID, and other sensor capabilities, to significantly improve the operational effectiveness and efficiency of warehouse inventory checks and yards. “All large companies are looking at how robots - in one form or another - can be applied to their environments,” says Matt Yearling, CEO at PINC. “An Aerial robot/drone is no different. The whole point of the operation is that it shouldn’t add to the workload of the operation; people just want to push…

Found in Robotics News & Content, with a score of 8.03

Inventory control at the warehouse level is simple, right? You just need to follow warehouse management system processes, set some minimum SKU levels, and be diligent about scan verifications to track consumption. While that worked 20 years ago, in today’s world, with automated systems to store inventory, you may need a warehouse execution system or WES. Forget global supply chain snarls for a moment, and consider another changing reality for inventory management—the increasingly complex flow of goods and transactions in fulfillment centers. While warehouse management systems (WMS) have long been responsible for inventory control in distribution centers (DCs), this complexity…

Found in Robotics News & Content, with a score of 8.02

…workflow in a typical distribution warehouse today: Warehouse Receives inventory Warehouse Stores & Manages inventory Warehouse Ships inventory (Repeat - forever) The general process hasn't evolved much. The beauty is in its simplicity. But when Step 2, the Storing & Managing of inventory, is inefficient, everything else breaks down. It's the hub that keeps Shipping and Receiving running smoothly. Today, there's more technology than ever helping make the same processes work better: computers, forklifts, conveyor belts, a bit of automation, and the people that keep it all together. But even with all this new technology there still exist some fundamental…

Found in Robotics News & Content, with a score of 7.84

…Using its fork arms, the robot can access the inventory rows of varying depth placed as low as 285mm (11.2 in.) and as high as 7,820mm (307.8 in. or 25.6 ft.), targeting horizontal as well as vertical warehouse space. Equipped with an intelligent depth camera and high-precision sensors, the robot can adjust its arms to pick boxes of varying sizes, optimizing overall shelf space, said Geek+. The storage location can also be allocated according to the size of the box, improving inventory organization. Connected to a warehouse management system (WMS) and driven by intelligent algorithms, the robot can autonomously transfer…