Editors’ Picks

Found in Robotics News & Content, with a score of 23.74

…partners.” FABTECH is North America's largest metal forming, fabrication, welding, and finishing event, according to organizer SME. KUKA will feature product demonstrations at Booth B27051 at McCormick Place in Chicago from Sept. 11 to 14. KUKA to display educational carts “ready2_educate_arc is a mobile, all-in-one training cart that provides fast and accurate robotic welding programming, operation, and even the manufacturing of small parts,” said KUKA. “It is ideal for schools, universities, and company training.” The cart can fit through standard-size doors and can be used without the welder for general training, the company noted. It also includes a fume extractor,…

Found in Robotics News & Content, with a score of 9.52

…anything from bin picking and heavy-load palletizing to ship welding. This variety is reflected in the UR Academy, which offers a range of courses ranging from virtual e-learning to in-depth and in-person classroom training. Universal Robots has 119 training centers around the world, with more opening soon. “No matter the task or the size of your company, you can find relevant training that can help you become even more successful with your automation,” said Vahl. “And we can see it works—customers who do take training with us are ultimately more successful and confident.” In addition, The Odense, Denmark-based vendor noted…

Found in Robotics News & Content, with a score of 17.06

…by serving as a dedicated fabrication space for in-house welding and painting of masts and frames. The facility will also integrate cutting-edge technologies such as Mixed Model Line Design, Industry 4.0 process monitoring, and one-piece flow. The company added that the expansion of robotic welding, along with the optimization of paint capacity and weld fixtures, will contribute to its ongoing focus on improved efficiency. Ken Barina, president of Mitsubishi Logisnext Americas, and Jay Gusler, executive vice president of Mitsubishi Logisnext Americas, led the groundbreaking ceremony. The company said it expects construction to be complete in the first quarter of 2024.

Found in Robotics News & Content, with a score of 32.62

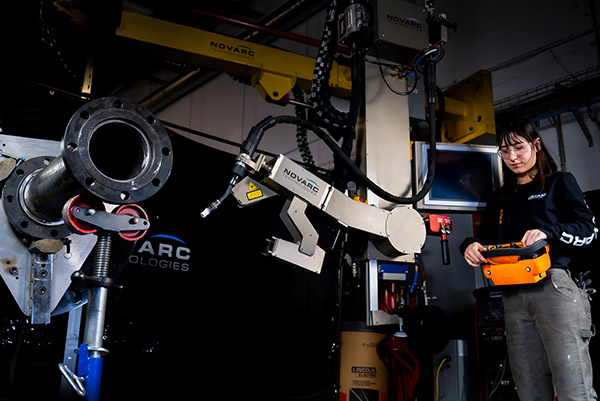

…which is using artificial intelligence and robotics to address welding applications. “We are thrilled to welcome Caterpillar as an investor in Novarc,” said Soroush Karimzadeh, CEO of Novarc Technologies, in a release. “Their extensive industry expertise and global presence align perfectly with our goals.” “This investment will fuel the development of Novarc’s AI robotic welding solutions, enabling us to revolutionize the future of welding in manufacturing automation and beyond,” he said. Novarc develops welding 'full stack' Novarc Technologies claimed that its team is dedicated to solving welding automation problems and improving customers' bottom lines. Fabrication facilities are increasingly recognizing that…

Found in Robotics News & Content, with a score of 9.94

…internal and external defects and autonomously repair them using welding, milling, and grinding processes. Robel Rail Automation is currently implementing a stationary repair system to test the individual process steps on new and used switches. FANUC robots weld a rail. Source: FANUC European railway networks are already running the first prototype systems, and Robel said it expects the system to be commercially available in two to three years. The Bavarian company added that its system will safely perform continuous maintenance work and help conserve resources. In addition to robots and camera systems, the repair wagon includes integrated scanners, ultrasonic devices,…

Found in Robotics News & Content, with a score of 7.37

…“This involves cognitive industrial robots for applications such as welding, warehousing, gluing, sanding, and assembly,” explained Reger. “However, this volume only describes the minimum delivery volume over the next five years. The actual demand of our customers is much higher, but currently still limited by our production capacities.” “For a better classification of the demand as a whole—the order volume mentioned results from just one-time 14 contracts,” he noted. “We currently have around 100 more contracts under negotiation. That is why the new capital is so important, because we need to expand our production capacities very quickly.” NEURA is developing…

Found in Robotics News & Content, with a score of 2.94

…Assembly tasks include tightening nuts and bolts, soldering and welding, inserting electrical connections, and routing cables. Robotic assembly, however, is a long-standing work in progress. That’s because the physical manipulation complexity, part variability and high accuracy and reliability requirements make it extra tricky to complete successfully — even for humans. That hasn’t stopped researchers and developers from trying, putting simulation to work in these interactions involving a lot of contact, and there are signs of progress. NVIDIA robotics and simulation researchers in 2022 came up with a novel simulation approach to overcome the robotics assemble challenge using Isaac Sim. Their…

Found in Robotics White Papers & Archives, with a score of 22.34

…robotic arm is essentially useless. Whether it’s a gripper, welding torch, camera, or something else entirely, end effectors are the component that allows the robotic arm to accomplish its task. With the expansion of robotic arms as an automation solution, it’s more important than ever to understand the ins and outs of end effectors. End effectors are most commonly split up into three main categories: grippers, sensors, and process tools. Each of these has their own sub-categories (which will be touched upon later), but first it’s important to understand the differences between these first three categories. Read on to discover…

Found in Robotics News & Content, with a score of 7.46

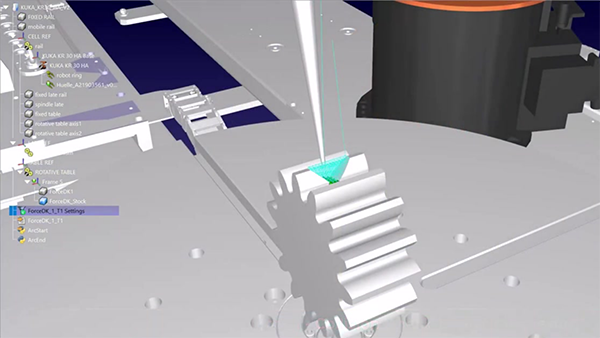

…mm takes time to carefully CNC.” Improve your laser welding initiatives with RoboDK industrial simulator RoboDK eliminates the need for shop floor programming and optimizes robot paths to avoid singularities, axis limits, and collisions. Due to its innovative design, coding experience isn’t necessary. By combining RoboDK with another system, such as the ESPRIT, Hexagon’s “Hybrid” CAM, companies can develop sustainable production processes. It reduces energy consumption and waste generated from their operations. Using RoboDK’s simulation and offline programming tools helps companies reduce production costs and downtime. Moreover, it minimizes hazardous materials produced in production cycles. These advantages make RoboDK an…

Found in Robotics News & Content, with a score of 15.27

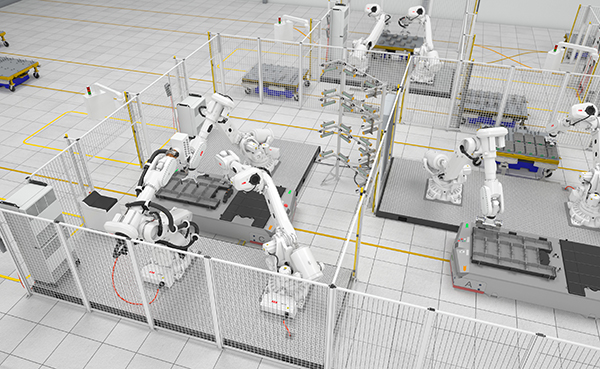

…of robots suitable for complex tasks such as spot welding, laser welding, screwdriving, and riveting, said ABB. This allows automotive manufacturers to achieve high-quality assembly, the Auburn Hills, Mich.-based company asserted. “Our new robot range meets the needs of the rapidly growing electric vehicle (EV) industry,” said Joerg Reger, managing director of the automotive business line at ABB Robotics. “As manufacturers ramp up production of EVs and batteries, they can choose from a wide range of ABB robots to ensure they have the right variant to handle batteries of varying sizes, from individual cells and modules to complete packages.” “They…

Found in Robotics News & Content, with a score of 17.40

…will also address this growing market. Diverse solutions for welding will prove a further attraction for exhibition visitors. FANUC partner LEWA Attendorn, for example, is planning to show a flexible and optimal answer to complex manufacturing challenges within an assembly process, while partner Demmeler's welding cell will centre on an intuitively programmable CRX collaborative robot for automated welding. Other partners, such as Wandelbots and voraus robotik, will demonstrate topics like “no code” programming and the Future Human Robot Interface. Last but not least, the company INperfektion is going to show a two-component gluing application using a FANUC CRX-20iA/L and 3D…

Found in Robotics News & Content, with a score of 11.92

…company said the robot is suitable for palletizing and welding applications. Powered by the same 5A output source, CS625 features a maximum payload of 25 kg (55 lb.) and a radius of 1500 mm (59 in.), slightly sacrificing reach for greater robustness, accuracy, and strength, Elite Robots said. Like all other models in the CS series, the CS620 and CS625 robotic arms feature an IP68 degree of protection and ISO Class 5 clean rooms, making them suitable for both harsh environments and those requiring a high level of hygiene. Elite Robot highlights scanning technologies Elite Robots will also showcase the…