Editors’ Picks

Found in Robotics News & Content, with a score of 2.64

…response to supply chain issues with China and localizing inventories with new “grey-collar” jobs managing robots. I think Erik Nieves, CEO of Plus One Robotics, said it best at the summit: “Well, it was clear that there was not going to be enough labor to manage all of the deliveries and the packaging as we continue to move our commerce online.” “But COVID acted as an accelerant to all of that, because right when we had the most need for the parcels and orders to flow is when we had the least reliable labor to do it,” he added. “And…

Found in Robotics News & Content, with a score of 2.63

…advantage of robotics? “One customer had $16.8 million in inventory in a queue for a quality-control check,” he said. “They handed it to us and said, ‘Do you have a way to get through this?’ We had to do a kaizen sort to reevaluate the whole process, but we ended up eliminating 95% of QC sort, freeing up 75,000 sq. ft. and reducing overhead so they could deploy employees elsewhere.” Wagner’s Oliaro cited an example of improving inventory accuracy with drones from partner Gather AI. “It would normally take a person in a reach truck or a scissor lift a…

Found in Robotics News & Content, with a score of 2.63

…the worker. Essentially, 3D printers can replace your just-in-time inventory. Already a reality, virtual warehouses can send 3D model files digitally to the nearest 3D printer. Logistics companies like DHL and UPS are already using 3D printing to supplement their “end-of-runway” services when specific parts are needed in the fastest time possible. Not everything should be 3D printed. But with its multiple benefits, 3D printing technology can improve the supply chain in ways that shouldn’t be overlooked. Jamie Howard is president of Ultimaker Americas, where he is responsible for the company’s commercial strategy and business execution in the Americas region.…

Found in Robotics News & Content, with a score of 2.61

…potential use cases, said Nielsen. They include cleaning robots, inventory scanning robots, and assistive-pick AMRs. It is inevitable customers will have AMRs from multiple vendors, with a resulting need for a layer of “interfleet management” software. Nielsen said that MIR isn’t developing this capability itself, adding that some of its customers are looking at using software from Amazon Web Services (AWS) called RoboRunner for this purpose. Other Automate exhibits of interest SVT Robotics had a sizeable booth at Automate. The vendor, which offers a software platform to speed and simplify integration of robotics solutions with host systems like a warehouse…

Found in Robotics News & Content, with a score of 2.60

…help GEODIS e-commerce warehouses efficiently manage order picking and inventory replenishment, significantly increasing throughput to speed delivery processes, said Locus. The AMRs significantly reduce unproductive walking time, eliminate the need for people to maneuver heavy manual carts through warehouses, lower the physical demands on employees, and improve workplace ergonomics and quality, it said. In addition, GEODIS said the robots reduce tedious, repetitive tasks and increase worker retention across its sites. The company said this allows it to enhance its operations and meet evolving customer needs. Locus Robotics to expand global footprint Locus said its AMRs collaborate with human workers to…

Found in Robotics News & Content, with a score of 2.59

…slow-moving items, noted OSARO. The kits can also make inventory management more predictable for both retailers and fulfillment operators, it said. In addition, consolidation of products in kits can reduce packaging and shipping costs, said the San Francisco-based company. While warehouses may have automated storage and retrieval systems (ASRS) and fleets of autonomous mobile robots (AMRs), increasingly scarce human workers typically put multiple items into single boxes for kitting. It's a tedious, repetitive task. Solutions engineer Nick Coffin with a kitting robot. Source: OSARO OSARO said its Robotic Kitting System is designed to consistently identify, pick, and place SKUs. Adaptive…

Found in Robotics News & Content, with a score of 2.59

…performance by strategically managing the location of your fastmoving inventory, and the dynamic management of this. 4. NO TIME TO TRAIN NEW WAREHOUSE PERSONNEL You needn’t have to slow down your operations in order to make your new personnel trained within warehouse. During the pandemic some of our customers benefitted from our SynQ Virtual Reality (VR) Training Manager. Deployment of such software can ensure continuity of operations while delivering excellence in peaking skills. Have a look how can our customers continue their operations while having their new personnel trained. 5. MACHINES’ DOWNTIME - WHAT NOW? In case of interruptions in…

Found in Robotics News & Content, with a score of 2.57

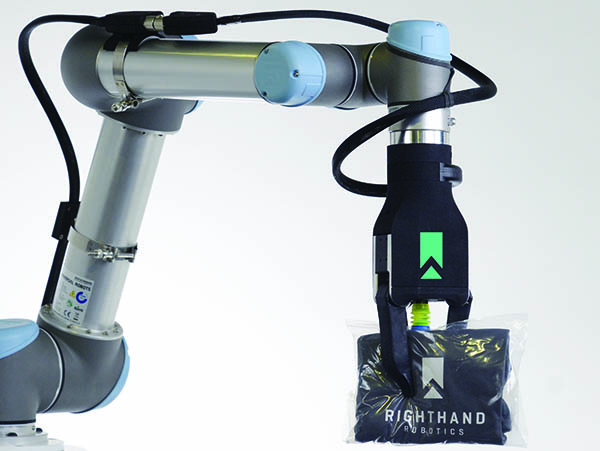

…online, this system transfers the proper item from its inventory storage location in the AutoStore cube storage zone directly into an outbound order container without any manual touch. The robot can pick and place thousands of different products, fulfilling e-commerce orders efficiently and correctly every time, said the companies. An AutoStore installation at Solar A/S, a leading European company serving the electrical, plumbing, and ventilation sectors, includes eOperator. Since the RightPick implementation, the company said its picking productivity has significantly increased. See RightPick and eOperator in action eOperator is available at two demonstration centers in Kløfta, Norway, and Bad Friedrichshall,…

Found in Robotics News & Content, with a score of 2.56

…and reporting and enabling businesses to identify trends, optimize inventory levels and measure asset health and reduce waste. Warehouse labor shortages a major driver In addition to helping warehouse operators address the automation interoperability gap, Honeywell said it also helping them alleviate labor challenges with automation solutions. The global labor force will face a shortage of 85 million workers by 2030 because of aging populations, changing demographics, and skills gaps, found McKinsey & Co. At ProMat 2023, Honeywell has demonstrated several technologies that are being deployed in warehouses and distribution centers to help operators increase efficiency and productivity with reduced…

Found in Robotics News & Content, with a score of 2.54

…for people to travel across a facility to retrieve inventory and deliver it to the packing station. In addition, inVia Pickers are mobile, unlike traditional shuttle systems, and they can be moved to work in different zones or in other locations. The company said this eliminates the need for re-engineering facilities, allowing inVia to adapt to different environments. The Frost & Sullivan Best Practices Awards recognize companies across the globe for demonstrating outstanding achievement and superior performance in leadership, technological innovation, customer service, and strategic product development. inVia said it was awarded based on its commitment to innovation, creativity, and…

Found in Robotics News & Content, with a score of 2.53

…system that manages a warehouse from the perspective of inventory and people activity, to one that can also manage activity in tight concert with automated systems. The march of ecommerce, labor shortage issues, and the addition of more automation makes an “automation aware” WMS approach a natural direction, said Elliott. “You can’t live now without automation in many warehouses. “You can’t just rely only on systems for managing people.” Automation-aware WMS will keep close tabs on machine and labor capacity issues, Elliott said, and provide visibility into automated machinery, such as whether goods are accumulating on a conveyor or a…

Found in Robotics News & Content, with a score of 2.52

…physical tasks such as mowing and knowledge work like inventory management, customer success, and marketing. The robots can explore, map, navigate, and manipulate the physical world around them, including homeowners associations (HOAs), parks, university campuses, and more, it said. “We started with large machines and then thought about scale for making them inherently safe,” he explained. “If the robot has to deliver ROI [return on investment], we just need a two or three DoF [degree-of-freedom] actuator product to be profitable.” Electric Sheep added that its robotic mowers don’t require an engineer on site – they can just be shipped to…