Editors’ Picks

Found in Robotics News & Content, with a score of 42.10

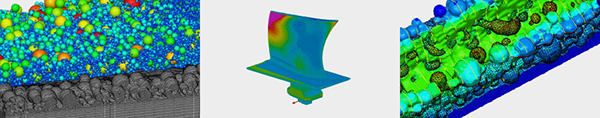

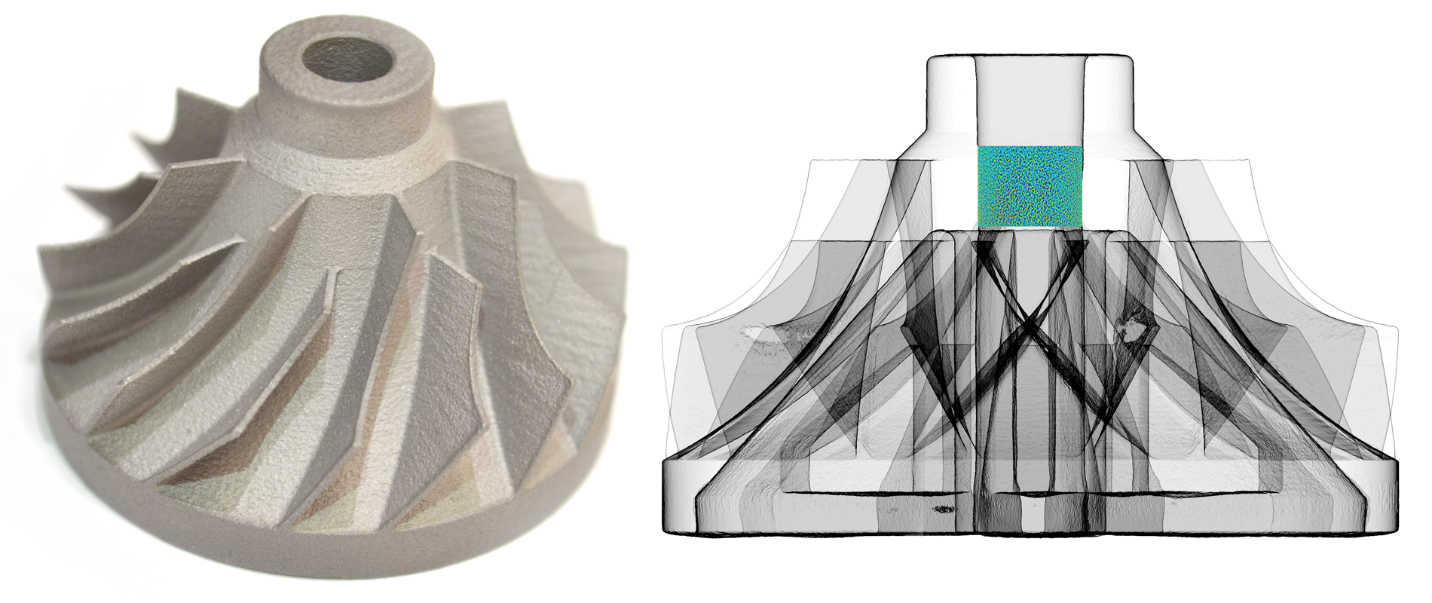

ESI Group has launched the ESI Additive Manufacturing simulation solution suite. The ESI Additive Manufacturing suite, according to the company, provides a comprehensive solution to accelerate metal additive manufacturing (AM) development. ESI adds that the solution suite enables users to quickly address manufacturability issues on the shop floor and that it also connects with material quality investigations. These characteristics, ESI says, make it a “perfect” solution to ensure efficient and continuous workflows from CAD through manufacturing and part qualification. This nacelle hinge was 3D manufactured using a powder bed fusion process. Click here for animation. Image supplied by ESI Group…

Found in Robotics News & Content, with a score of 9.37

…In addition to enabling the engineering workflow for late-stage prototyping, Method will also help organizations promote a design for additive manufacturing (AM) mentality among its engineering ranks. “Organizations that want their workforce thinking about AM have been limited in their ability to seed multiple units in the workspace,” he says. “Method is a good tool for organizations that want engineers and designers to be thinking about design for AM practices.”

Found in Robotics News & Content, with a score of 27.65

…2019. The aim of this collaboration is to leverage additive manufacturing to help address the issue of obsolete parts, reduce whole life rolling stock costs and enable vehicles to remain in passenger service for longer. This has the added potential to lower costs for train operating companies, as they can produce low run parts as needed, rather than mass manufacturing vast quantities, Stratasys reports. All parts have been designed for additive manufacturing and 3D printed using Stratasys’ Fused Deposition Modeling (FDM) technology. In addition, the components have been structurally assessed by ESG Rail for manufacturing using Stratasys 3D printed tooling…

Found in Robotics Companies & Businesses, with a score of 54.00

…designers and engineers make the unmakeable. Experts Focused on Accelerated Prototype Fabrication & Low- to High-Volume Production Part Services Additive, Traditional, & Hybrid Manufacturing Expertise with an Industry-Leading Advantage of Agility 3D Printing, Additive Manufacturing, CNC Machining, Urethane Casting, Tooling, & Injection Molding We are uniquely blending additive technologies and materials with legacy manufacturing methods so companies can go from concept to prototype to manufacturing in a way that wasn’t previously possible.

Found in Robotics News & Content, with a score of 15.89

…the deeper capabilities of microCT to parts produced by additive manufacturing (AM). One of the many benefits of metal AM is the ability to produce internal structures. Parts must not only meet dimensional specs but also display consistent and acceptable quality characteristics, such as high density and the absence of internal defects. MicroCT is a powerful tool for these and other AM applications, too, as described in a recent paper by Anton du Plessis et al, “X-Ray Microcomputed Tomography in Additive Manufacturing: A Review of the Current Technology and Applications” (Anton du Plessis, Igor Yadroitsev, Ina Yadroitsava, and Stephan G.…

Found in Robotics News & Content, with a score of 15.34

…chips away at one of the chief obstacles keeping additive manufacturing (AM) from taking on more demanding applications in the automotive, aerospace and medical equipment industries. An interdisciplinary team of researchers at Vanderbilt University has developed a technique that uses the optical properties of gold nanoparticles to detect and quantify missing layers in 3D-printed products. By scanning light across the surface of a printed object, engineers can identify defects in that material. Image courtesy of Vanderbilt University. Quality Control Challenges The new testing technique seeks to provide the means to identify defects during the manufacturing process. Missing print layers and…

Found in Robotics News & Content, with a score of 26.17

…Phillips Service Industries subsidiary) announced that its Electron Beam Additive Manufacturing (EBAM) process had achieved qualification for making the tanks after testing that was part of a multi-year development program with Lockheed. Lockheed Martin printed both halves of the 46-in. titanium fuel tank domes on an American-made Sciaky EBAM 110 machine. The tanks met or exceeded NASA’s performance and reliability requirements, which will allow the tanks to become a standard product option on LM 2100 satellites. “Sciaky's EBAM technology is now the world's only large-scale metal 3D printing process that has qualified applications for land, sea, air, and space,” said…

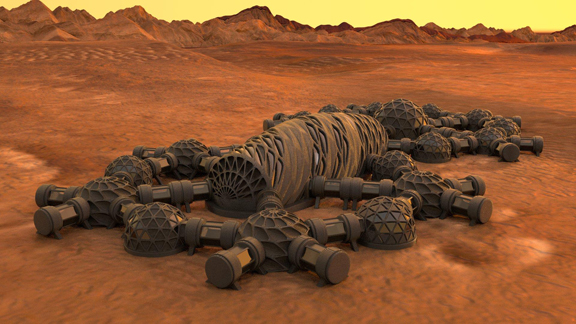

Found in Robotics News & Content, with a score of 9.71

…post explaining the project with NASA, Raymond Deplazes, Autodesk's Manufacturing & Research PR, writes, “NASA’s Swamp Works lab is experimenting with 3D-printing habitable structures using a process called robotic extrusion, and a composite material made up of loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids ... Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction.…

Found in Robotics News & Content, with a score of 21.28

…how technologies fit together with each other in Smart Manufacturing. The report identifies eight transformative technologies: ● Additive manufacturing ● Artificial intelligence (AI) and machine learning (ML) ● Augmented reality (AR) ● Blockchain ● Digital twins ● Edge intelligence ● Industrial Internet of Things (IIoT) platforms ● Robotics According to ABI, The manufacturing sector has already seen increased adoption of IIoT platforms and edge intelligence. Over the next ten years, manufacturers will start to piece together the other new technologies that will eventually lead to more dynamic factories less dependent on fixed assembly lines and immobile assets. Each step in…

Found in Robotics Companies & Businesses, with a score of 38.36

CRP Technology is one of the largest 3D Printing and rapid prototyping companies in Italy. It can count on production printers for additive manufacturing and this guarantees high quality standards for finished products, as well as multiple options for production. Thanks to the Windform line, this allows for the creation of highly-functional and beautifully finished parts suitable for multiple applications. CRP Technology 3D Printing materials have given birth to global products that require superior mechanical and aesthetic properties.

Found in Robotics Companies & Businesses, with a score of 53.09

We enable our customers to produce innovative and high quality products based on industrial 3D printing technologies. EOS is the global technology and quality leader for high-end solutions in the field of additive manufacturing (AM). Founded in 1989, we are a pioneer and world leader in the field of Direct Metal Laser Sintering (DMLS) and provider of highly productive Additive Manufacturing Systems for plastic materials.

Found in Robotics Companies & Businesses, with a score of 32.37

…been playing an active role in the field of Additive Manufacturing (AM) since 1990. In addition to having the largest single-site capacity of AM equipment in Europe, we have a strong reputation as a provider of innovative software solutions. We strive to use our expertise to create a beter and healthier world with 3D Printing and through biomedical and clinical solutions for medical image processing and surgical simulations. Our customers range from large companies in the automotive, aerospace and consumer electronics sectors; to famous hospitals, research institutes and clinicians; to individual consumers interested in bringing their own unique creations to…