Editors’ Picks

Found in Robotics News & Content, with a score of 0.35

…stronger over the past year, partly because of the COVID-19 pandemic. For instance, Photoneo's depalletization system can unload pallets laden with mixed types of boxes. Not only can its algorithms recognize regularly shaped and nicely ordered boxes, but also those that are damaged, placed randomly, or even tilted at an angle. Similarly, the AI can recognize parcels that may be piled up in a container or coming on a conveyor belt. The algorithms can localize and segment each parcel and sort them according to the application’s requirements. Photoneo's systems can process up to 2,250 parcels or 1,000 boxes in one…

Found in Robotics News & Content, with a score of 0.35

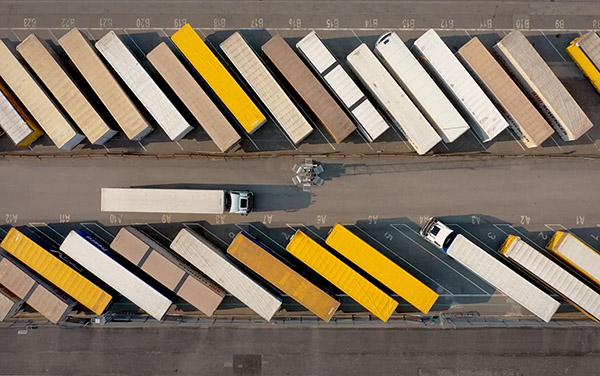

From trade conflicts and the COVID-19 pandemic to chronic labor shortages, supply chains have been under stress for the past few years. CloudSort Corp. claimed that it has “reimagined” how to move packaged goods, starting with the middle mile between distribution centers and warehouses. The Seattle-based company said its cloud-based network can optimize shipping operations through its partnerships with carriers and warehouses to sort cargo and increase its density, as well as more efficiently use warehouse space. Founded in 2019, CloudSort said it challenges the conventional “hub and spoke” transportation model, which is expensive to build and maintain and closed…

Found in Robotics News & Content, with a score of 0.34

…partly in response to travel restrictions due to the COVID-19 pandemic. They allowed 31 teams from 40 universities across four continents to test their artificial intelligence drivers and determine their readiness to compete in on-track competitions. The IAC said it plans to re-launch its simulation races with AWF “to expand the number of university teams developing and training novel AI driving algorithms.” The SIM races widen access for teams to participate in autonomous racing by reducing the barriers of funding or physical car availability, noted the organizations. “We worked closely with IAC to enable the reference autonomy software on the…

Found in Robotics News & Content, with a score of 0.34

…channel for us. We've felt the effects of the [COVID-19] pandemic on the supply chain. We have a partner in China that supplies processors, and we have different providers for the same piece of equipment. There's a new process and flow, and today isn't as bad as 2021. We continue to work with the Purdue University weed science lab in West Lafayette. For instance, water hemp is resistant to herbicide, so it's one of our goals for next season. Given the size of your potential market, how will you scale up to meet demand? Ferreira: Farmers are comfortable with robotics…

Found in Robotics News & Content, with a score of 0.34

…has experienced a 60% increase in disruption during the COVID-19 pandemic — more than any other industry. This has triggered a push to move critical processes stateside. However, using traditional factories for reshoring can introduce new challenges, such as higher-priced products because of companies' inability to take advantage of the cost efficiencies they enjoyed in other countries. Machina Labs said it can eliminate many of these supply-chain bottlenecks through its cost-effective, fast, and efficient manufacturing processes. Machina Labs pilots in aerospace, defense Some of Machina Labs' current customers are in the aerospace and defense industries. Having completed pilots with NASA…

Found in Robotics News & Content, with a score of 0.34

…automation can help supply chains cope with peak demand. COVID-19 continues to reshape retail We saw a spike in e-commerce during the COVID-19 pandemic, but some activity has shifted back to brick-and-mortar retail. How does that affect retailers and warehouse operators? Dryer: The trend of past 20 years has been toward more online and omnichannel activity, then COVID accelerated everything. I have spoken with many customers that had built their networks for three to five years, but that capacity got consumed within a few months. Companies have a choice of more automation, expanded facilities, or networking to add capacity. Five…

Found in Robotics News & Content, with a score of 0.34

…work paid off, helping staffers maintain social distance from COVID-19 patients with arrythmias,” said Fischel. “With remote collaboration, physicians in Italy and Portugal could help each other and share interoperative maps.” Magnetic system finds success in Monaco Stereotaxis this week announced that its Genesis system was installed at the Princess Grace Hospital Center in Monaco. Electrophysiologists at the hospital have been using Stereotaxis' technology in 2006. Since then, more than 1,000 patients in Monaco have benefited from the system's precision and safety, said the company. Dr. Gabriel Latcu, head of electrophysiology and deputy head of cardiology services at Princess Grace…

Found in Robotics News & Content, with a score of 0.34

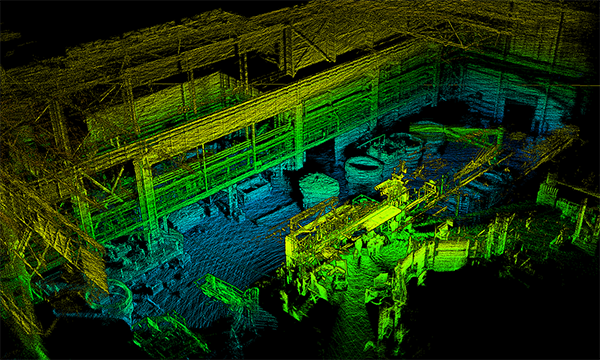

…highly visible role of drones in responding to the COVID-19 pandemic, and advances in 5G networking and edge processing. Similarly, Markets and Markets forecast a CAGR of 55.9% for the commercial drone services market, growing from $4.4 billion in 2018 to $63.6 billion by 2025. It noted increasing development of industry-specific applications such as inspection and delivery, particularly in the Asia-Pacific region. “We're not just selling the data or the hardware,” said Rabkin. “There's an opportunity to make the business model sensitive to the financial model. For example, if you charge per inspection, the value of the inspection has to…

Found in Robotics News & Content, with a score of 0.34

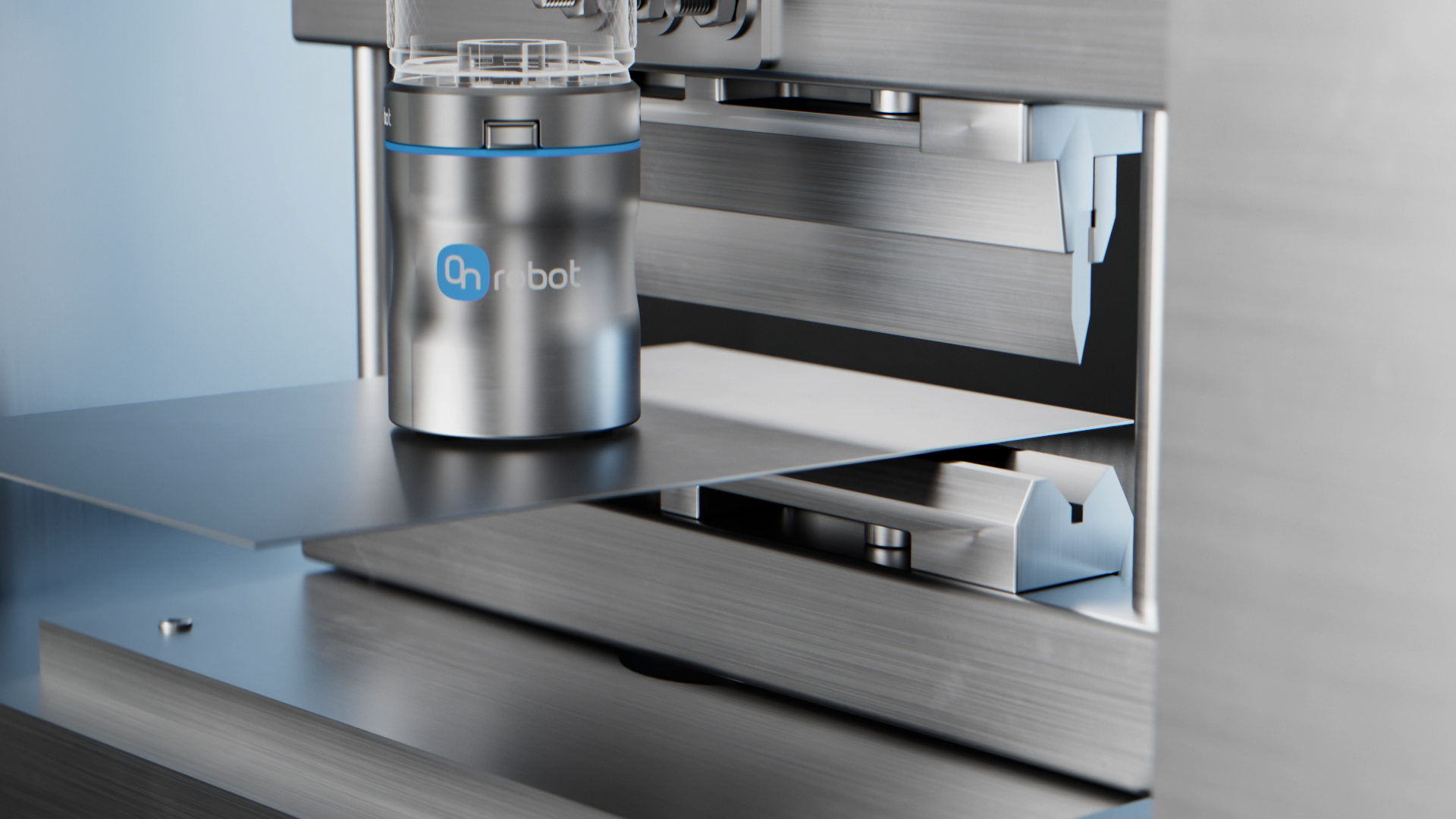

…particular found contracting markets in 2020 because of the COVID-19 pandemic. However, the demand for robot flexibility is changing and growing. Warehouse and distribution center operators face challenges retaining workers, and end-of-line tasks such as palletization can cause strain and are costly, according to gripper maker OnRobot. The company said its latest grippers meet the need for easier-to-use robots. “Safety was the initial consideration for cobots, but we've come so far toward plug and play,” said Kristian Hulgard, general manager for the Americas at OnRobot. “The next big things are ease of use and deployment time.” Odense, Denmark-based OnRobot A/S…

Found in Robotics News & Content, with a score of 0.34

…for repetitive tasks has become more difficult during the COVID-19 pandemic. As online shopping doesn’t show any sign of slowing down, more merchants are applying robots to order picking. At the same time, people are still needed for upstream and downstream processes. That’s where collaborative robots, or cobots, come into play. Collaborative robot arms and AMRs are different from industrial robots because they include sensors and programming to avoid dangerous interactions with humans. They are also potentially easier to operate, reducing the need for technical experts in production. Cobots include the following features, depending on the application: Safety-monitored stop: Such…

Found in Robotics News & Content, with a score of 0.34

…the workforce altogether due to concerns or constraints around COVID-19. Now it’s up to employers to address the labor shortages. Some industries are feeling the strain more than others, particularly those that faced hiring and retention challenges long before the current wave of “quits.” This includes the warehousing and distribution sector. Why the growing labor shortage? The older generation of warehouse workers is gradually retiring, opening up many positions for young job seekers. But fewer and fewer are interested in the physically demanding, injury-prone nature of warehouse work. What does that kind of work entail? In a traditional warehouse environment,…

Found in Robotics News & Content, with a score of 0.34

…much more agile business. For example, during the current COVID-19 crisis, many of our customers have seen unanticipated peaks as the demand on ecommerce spiked. They were able to rapidly add additional Chucks and temporary labor to adjust for this demand, far more quickly than otherwise possible. And in some cases, they picked up and moved Chucks across their different facilities to support regional spikes in volume. Temporary and portable capacity is something that no traditional automation can offer. Related: See how keeping their automation solution flexible allowed DM Fulfillment Services to thrive in uncertain times. Final thoughts Increasing productivity…