Editors’ Picks

Found in Robotics News & Content, with a score of 29.05

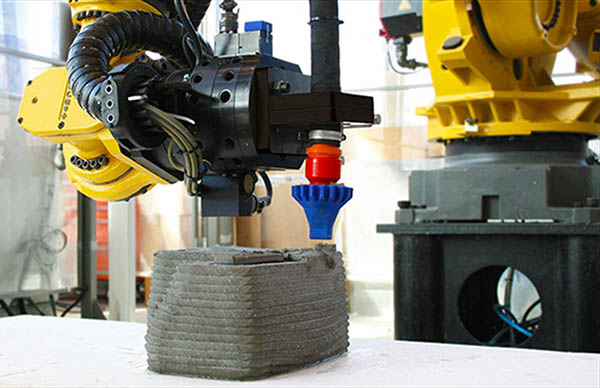

…month published Wohlers Specialty Report on Construction: Building an Additive Construction Future. The report detailed developments in additive construction, or AC, an industry that is rapidly growing in response to opportunities created by additive manufacturing and 3D printing. Standards organization ASTM International acquired Fort Collins, Colo.-based Wohlers Associates in 2021. The advisory group now includes technical and market experts to support the growing additive manufacturing (AM) industry. “ASTM International sees AC as the next frontier in construction,” noted Terry Wohlers, head of advisory services and market intelligence at Wohlers Associates. “To gain a view of what is ahead, it is…

Found in Robotics News & Content, with a score of 24.59

Markforged Inc. yesterday announced that its manufacturing facility in Billerica, Mass., has met the rigorous quality management and quality assurance standards of ISO 9001:2015 to obtain certification from TUV Rhineland of North America. The additive manufacturing company said the certification will help streamline the supplier audit process. “Reliability is key for additive manufacturing. We're trying to help manufacturers meet traditional standards of quality, accuracy, strength, etc.,” Shai Terem, president and CEO of Markforged, told Robotics 24/7. “Without industry certification, that effort has been done application by application, one customer at a time.” Markforged said its Digital Forge is designed to…

Found in Robotics News & Content, with a score of 13.75

SME, a nationally recognized certifying body in manufacturing, announced last week that it has developed and will offer the Robotics in Manufacturing Fundamentals, or RMF, credential. The new certification focuses on assessing a candidate's comprehension of fundamental robotics concepts. It is designed for workers currently looking to upskill or reskill into manufacturing careers before pursuing equipment-specific or career pathway-specific training in robotics. The credential can help individuals begin a lifelong career in an industry where there is opportunity for advancement and good-paying jobs, according to the organization. SME developed the RMF credential with two leading organizations in the robotics education…

Found in Robotics News & Content, with a score of 21.29

…announced the release of new Simulation features for its additive manufacturing software. Simulation is available as a free trial until April 2023 and as a paid subscription thereafter, said the company. As both 3D printing and simulation software move from prototype to production, the complementary technologies promise to save manufacturers time and money previously spent on design/print/break testing cycles, according to Markforged. The Watertown, Mass.-based company said Simulation enables virtual testing of materials and designs for demanding applications. “This conversion of hardware, software, and materials comes down to confidence,” said Doug Kenik, principal product manager at Markforged. “Without Simulation, additive…

Found in Robotics News & Content, with a score of 19.63

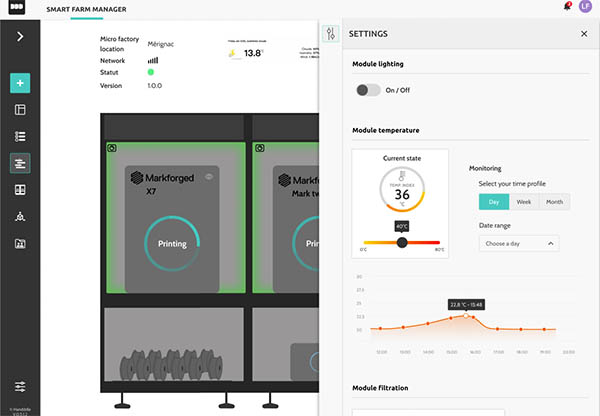

Environmental conditions such as temperature and humidity can affect additive manufacturing, so process monitoring can help standardize production. Handddle and Markforged yesterday said they are integrating Handddle's “micro-factories” platform and other management tools with the Markforged Digital Forge software. “Handddle is thrilled to collaborate with Markforged to extend API integrations for Handddle and Markforged users looking to achieve industrial efficiencies to address quality challenges in strategic markets,” said Dylan Taleb, co-founder and chief operating officer of Handddle. “Thanks to this collaboration, manufacturers will be able to rely on an integrated solution to develop their knowledge and control of production processes…

Found in Robotics News & Content, with a score of 22.86

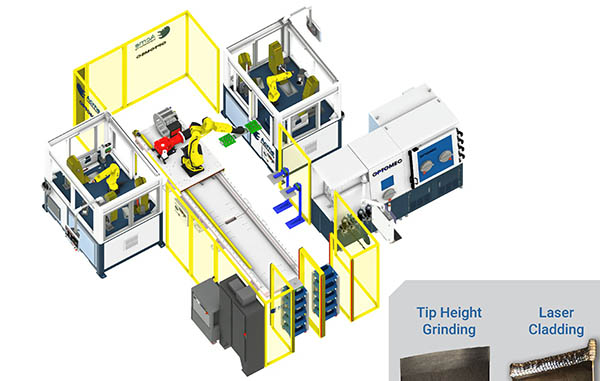

Additive manufacturing and robotic material removal systems are coming together. Optomec Inc. and Acme Manufacturing yesterday said they have partnered to produce an automated workcell initially optimized for repairing aviation compressor blades made of titanium. The companies have collaborated for two years with input from commercial maintenance, repair, and overhaul, or MRO, and U.S. Department of Defense repair centers for aircraft engines. “Our collaboration with Acme Manufacturing has brought together complementary technologies that provide a compelling business case for customers,” stated Mike Dean, vice president of marketing at Optomec. “Demanding repair requirements, driven by commercial and DoD repair centers, has…

Found in Robotics News & Content, with a score of 4.78

…recently announced plans to acquire Digital Metal, showed how additive manufacturing of metals and other materials has moved from prototyping to production. The company said it expects to move from Watertown, Mass., to Waltham, Mass., later this year. Siemens also explained the value of simulation and 3D printing for industrial use. Educational institutions share robot research The University of Massachusetts (UMass) Lowell showed Digit, a bipedal robot from Agility Robotics Inc. While Tesla Inc. had revealed the latest version of its Optimus humanoid last week, Digit is already available for research and warehouse use. Agility Robotics' Digit humanoid, displayed in…

Found in Robotics News & Content, with a score of 5.86

…modular architecture and “intensive topological optimization,” taking advantage of additive manufacturing and materials science. It weighs between 1.4 to 2.1 kg (3 to 4.6 lb.), depending on the configuration, and it can carry up to 5 kg (11 lb.). Thanks to a telescopic linear air-operated actuator, the EOAT can grasp parts the size of a golf ball or small blister pack, depending on the suction cup arrangement. It can hold a wide range of shapes and surfaces, even loose or nonrigid objects, said the company. The MAXXgrip's actuation is designed so it can be executed in parallel with the approach/depart…

Found in Robotics News & Content, with a score of 29.37

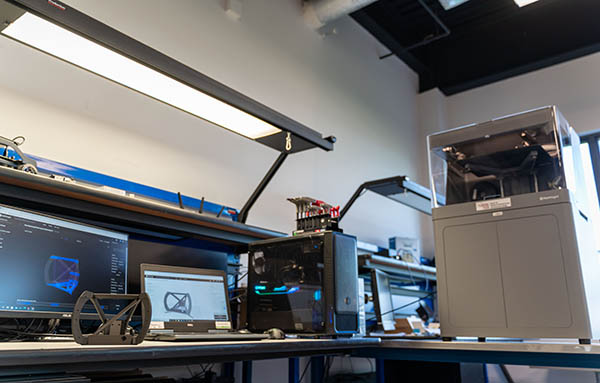

From prototyping to production, 3D printing and additive manufacturing have moved out of the lab and into factories and shop floors. If you're looking to create a fully effective 3D printing setup, then you'll want to know the most efficient way of doing so. There are lots of things to consider. In addition, you need to avoid common pitfalls. Here are five tips for setting up a 3D printing workflow. 1. Get set up for additive printing There have been huge advances in 3D printing in recent years, and that's why businesses from medical device makers and sporting goods manufacturers…

Found in Robotics News & Content, with a score of 8.43

…it launched in the past year at the International Manufacturing Technology Show, or IMTS 2022, next month. The show runs from Sept. 12 to Sept. 17 at McCormick Place in Chicago. The Zurich, Switzerland-based company will display its GoFa collaborative robot equipped for welding; a live 3D printing demo featuring ABB’s 3D Printing PowerPac for ABB’s RobotStudio simulation and offline programming software; the MiniMAC robotic grinding cell from ABB Value Provider MESH Automation; a vision guided FlexLoader machine tool tending cell; and the Cobot FlexTrainer education cell for interactive classroom training. “ABB has continually developed cutting-edge products and support programs…

Found in Robotics News & Content, with a score of 6.96

…focused on rounding out key functions in supply chain, manufacturing, and quality,” said Allgood. Falls and electrocution are among the leading causes of workplace fatalities, according to the Occupational Safety and Health Administration (OSHA). Utilities inspection and maintenance are dangerous and often occur in difficult weather conditions. Sarcos' Guardian XT, which recently completed beta development, is a roughly humanoid design with two arms and stereo cameras that can be mounted in a lift basket for work at height while keeping the operator safely on the ground. The Guardian DX is a variant for the defense industry. With HP Reverb virtual…

Found in Robotics News & Content, with a score of 10.68

…is increasing worldwide, as increasingly sophisticated software, robots, and additive manufacturing make production quicker and more efficient. The software development journey typically starts with the creation of the user interface portion, as outlined by Maryville University. Programmers eventually move on to craft the code that processes, analyzes, and responds to the data collected by robots and other systems. Developers must constantly learn about specific processes to retrofit code or hardware to evolving business and market needs. For the plastics industry, integrated robots and software offer innovative solutions for manufacturing challenges. Let's explore the many roles that robotics can play in…