Editors’ Picks

Found in Robotics News & Content, with a score of 12.19

…center of a volume printing solution for production 3D manufacturing. The printing system counts BASF, Materialise and Siemens as strategic partners, creating what HP calls “a new global community of proven large-scale 3D printed parts providers.” The printer is the latest refinement of HP’s work in Multi Jet Fusion (MJF) printing technology, which prints on a line-by-line basis. HP says the method is inspired by its long history of 2D wide format printing, but relies on a variety of innovations for 3D. HP says MJF allows for faster cooling and increased automation of post-processing compared to selective laser sintering (SLS).…

Found in Robotics News & Content, with a score of 12.08

…the annual AeroDef Conference, produced by the Society of Manufacturing Engineers (SME). “I'm a competitor. I look out in the audience and I see my competitors, suppliers, and customers,” said Kevin Smith, sector VP of Global Operations, Northrop Grumman Aerospace Systems, as he began his keynote talk. “But there are a couple of things I won't compete on .. [ That's ] any type of safety products. [If there's] something I can do to help my industry friends be successful in the area of safety, I don't want to compete in that area. I'd share my capability and collaborate with…

Found in Robotics News & Content, with a score of 11.99

…project from Department of Defense (DoD) to develop an Additive Manufacturing (AM) process capable of mass producing Cobalt-free hardmetals, developed by the U.S. Army. The company’s Production System with Single Pass Jetting (SPJ), an AM technology developed by Desktop Metal, will mass manufacture complex shaped Co-free hardmetal parts without tooling and is expected to lead to the development of a dual-use technology with numerous applications in DoD as well as in the civilian sector. This new process has the potential to change the landscape of the carbide hardmetals market which is projected to grow to $24 billion by 2024 and…

Found in Robotics News & Content, with a score of 11.98

…$12 billion by 2028, as more companies turn to additive manufacturing to create production parts in the automotive, aerospace and other industries. Giants such as HP and GE have launched large-scale metal printing efforts, but other companies have focused on smaller units that can be used for design and prototyping, as well as low-volume runs of metal production parts, tooling and molds. “Metal printing has been one of the best growth stories in 3D printing, and I think that is because current powder bed technologies are uniquely suited for advanced manufacturing,” says Kevin McAlea, executive vice president and chief operating…

Found in Robotics News & Content, with a score of 11.88

Projects that leverage additive manufacturing and 3D printing to create really big objects have gotten a lot of attention. Massive robotic printing systems have been developed to create everything from cars to entire buildings. Those big 3D printers are impressive, but printing very small objects is actually a lot harder. Getting high resolution at smaller scales is difficult, and there are limits to just how detailed you can get once you move into nanoscale territory. Researchers at MIT appear to have found a way around this problem by printing small objects and then shrinking them to even tinier sizes after…

Found in Robotics News & Content, with a score of 11.75

…compromising strength, according to the company. “For design and manufacturing engineers, one of the most frustrating processes is ‘dumbing down’ a CAD file to STL format, only to require subsequent re-injection of design intent into the STL printing process,” says Mark Walker, lead software product manager at Stratasys. “This software is engineered to do away with this complexity, letting designers reduce iterations and design cycles, getting to a high-quality, realistic prototype and final part faster than ever before.” With CAD-native build controls, the solution doesn’t require manual generation of complex toolpaths. Intuitive features achieve desired part characteristics through automatic control…

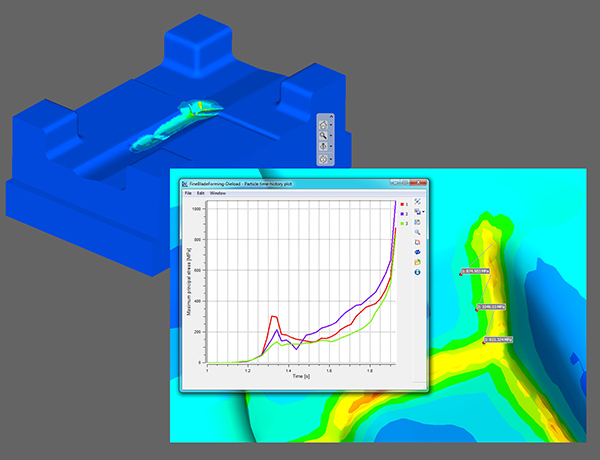

Found in Robotics News & Content, with a score of 11.62

…a simulation and analysis software suite for modeling complex manufacturing machines and forming processes. Rewritten throughout for increased efficiency and ease of use, Forming Version 16 also offers various new features and enhancements for building robust simulation models. The new geometry data check feature allows users to identify simulation error as well as check their position within the geometry. This new model data can be sent back to the CAD model, allowing retracing of corrections. The user then reimports the optimized tool geometry and continues setting up the model. Simulation of a carrier in MSC Simufact Forming Version 16. Image…

Found in Robotics News & Content, with a score of 11.51

…trio said they identified the need to scale up additive manufacturing (AM) processes for large-scale applications such as bespoke concrete formwork. “Currently, to develop a lightweight carbon-fiber element or to build a topologically optimized concrete floor slab, buyers would have to wait months and spend vast sums of money to receive a first sample and only then build a prototype, let alone consider reiterating for any flaws,” said SAEKI's founders in a release. “With SAEKI, this bottleneck is removed, enabling buyers to rapidly innovate and grow their services and offerings in ways they have not been able to before,” they…

Found in Robotics News & Content, with a score of 11.46

…validation and verification, the company says.. “Design, engineering and manufacturing practices are changing at lightning speed — organizations are leaning on simulation and digitizing their processes to bring cutting-edge products to customers faster than ever,” says Shane Emswiler, vice president and general manager for ANSYS electronics, fluids and mechanical business units at ANSYS. “This release empowers customers to do more with multiphysics simulation in less time. ANSYS 2019 R2 automates simulation while making it easier to use.” Highlights of the ANSYS 2019 R2 release include: ANSYS 2019 R2 introduces a user interface in ANSYS Mechanical that speeds user adoption and…

Found in Robotics News & Content, with a score of 11.46

…juncture in the advancement of metal 3D printing and additive manufacturing,” says Ric Fulop, CEO and co-founder of Desktop Metal. “We are excited about Koch being an investor, customer and capability provider in this round. This new funding will fuel the continued development of our metal 3D printing technology and rich product roadmap, the scaling of operations to meet a growing demand of orders, and the financing of major new research and development initiatives.” Early customers of the Studio System include: Ford, Stanley Black and Decker, Goodyear, 3M, Google’s ATAP, BMW, ProtoLabs, Owens Corning, L3, TerraPower, Medtronic, Continental AG, Applied…

Found in Robotics News & Content, with a score of 11.45

…Technology Collaborative last week held its third annual Massachusetts Manufacturing Mash-Up at Polar Park, showcasing collaboration among business, academia, and government to innovate, educate, and grow. About 1,500 people attended the event, 25% growth over 2022, according to the event organizers. This year's Mash-Up included the 8th Annual Manufacturing Awards Ceremony, the announcement of the Massachusetts Manufacturing Accelerate Program (MMAP) grant winner, and exhibits by technology companies, as well as student networking and challenges. “Our organization is proud to support, help scale, and celebrate the Massachusetts manufacturing ecosystem at this incredible event, and we’re humbled by the growth over the…

Found in Robotics News & Content, with a score of 11.44

…Northeast Ohio region. Freshmade 3D has also received development support from America Makes, part of the National Network for Manufacturing Innovation established by the Revitalize American Manufacturing and Innovation Act of 2014. “We’re so proud to be a part of Freshmade 3D’s success,” said Barb Ewing, CEO of the Youngstown Business Incubator. “Two of the three founders started their entrepreneurial career as part of our team. They are proof that Northeast Ohio is fast becoming the epicenter for additive manufacturing in North America.”