Editors’ Picks

Found in Robotics News & Content, with a score of 12.79

…and medium-sized enterprises (SMEs) are often challenged to deploy additive manufacturing (AM) technology because of the high cost of entry. A European Union (EU) program can help address this challenge. The EU-funded AdditiveManufacturABLE (AMable) program is helping SMEs develop their ideas into final products, as well as creating a digital framework to provide access to European AM knowledge. According to the Community Research and Development Information Service (CORDIS), the EU’s primary source of results from funded projects, AMable plans to open a new call for proposals in July. The AMable project was launched “to speed up the adoption of AM…

Found in Robotics News & Content, with a score of 12.77

e-Xstream engineering, part of Hexagon’s Manufacturing Intelligence division, has introduced simulation and virtual manufacturing capabilities that enable users to analyze the production cost of polymer-based additive manufacturing parts against conventional processes, and continuously improve virtual engineering processes by validating the composite’s microstructure with computing tomography scans of manufactured parts. The latest Digimat software enables businesses to simulate the 3D printing process and calculate the total cost of producing each part including the material use, employee time, energy and required post-processing steps. Using this new tool, an engineer can take a holistic view of part production and finishing processes to determine…

Found in Robotics News & Content, with a score of 12.69

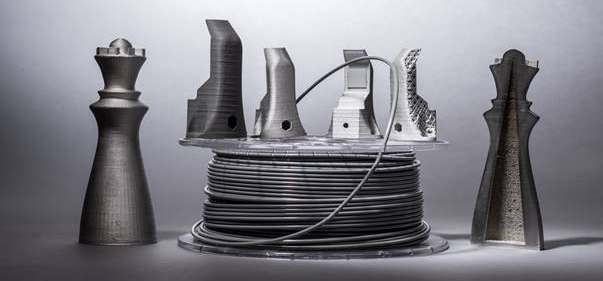

…Minec, managing director, BASF 3D Printing Solutions. “Our goal was to develop a high-quality metal filament that makes the additive manufacturing of metal parts considerably easier, cheaper, faster, and accessible to everyone.” Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 12.61

…quality prints at high volumes, making it an ideal additive manufacturing partner for the dental industry,” says Keystone Dental President Ira Rosenau. Nexa3D’s NXE 400 3D printer features LSPc technology that combines build volume, print uniformity, advanced process algorithms, modular design for onsite automation and intelligent optimization, the company says. Offering a 16-liter build volume and productivity gains, the NXE 400 printer yields part-throughput gains while offering low cost of ownership in its class on the market, the company says. Nexa3D enters the dental market with all of Keystone’s KeyPrint resins, including KeySplint Soft, a material that delivers a combination…

Found in Robotics News & Content, with a score of 12.59

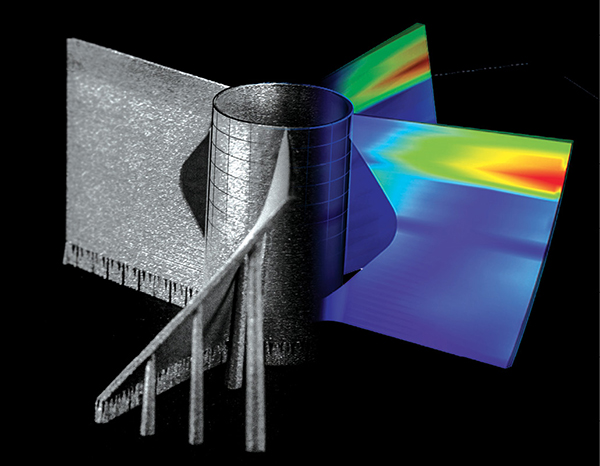

As more companies use additive manufacturing (AM) processes to create end-use metal parts (not just prototypes), quality and scrappage issues associated with AM have become a bigger issue. Many 3D printing technologies have demonstrated high degrees of variability regarding consistent parts creation, and because design for AM skills are often in short supply at most companies, there is great trial and error involved in creating usable parts. That has resulted in a high percentage of scrap and wasted materials. To reduce waste and improve part quality, end users need a way to virtually test builds before creating physical parts. An…

Found in Robotics News & Content, with a score of 12.58

…with eyes and brain. In simple terms, the jetting-based additive manufacturing system employs machine vision and machine learning/artificial intelligence (AI) capabilities to learn the properties of materials, predict behavior, and adjust printing over time. The goal: High precision, multi-material production-grade output. The start-up company, spun out from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) in 2017, is based on research led by Professor Wojciech Matusik and intellectual property licensed from MIT. Inkbit saw reason to create a new platform for 3D printing because while they believed there was substantial opportunity for ink jet AM capabilities, the technology was only…

Found in Robotics News & Content, with a score of 12.50

…problems. Omron's Asia-Pacific group this week announced its “innovative-Automation” manufacturing concept, based on its “three I's” or innovations of digital engineering transformation, letting machines do what they can do beyond human abilities, and advanced collaboration with people. Omron Automation Americas is based in Hoffman Estates, Ill. In November 2021, the industrial automation provider acquired a 10% stake in collaborative robot maker Techman Robot and opened a proof-of-concept center in Novi, Mich. California center to work on controllers Omron said its California expansion enables it to develop highly precise, high-speed motion technology that fits the needs of customers in the semiconductor,…

Found in Robotics News & Content, with a score of 12.50

…printing gains increasing support a feasible alternative to traditional manufacturing, it also creates opportunity for a wave of new cybersecurity risks, from theft of design intellectual property (IP) to malicious destruction of parts and planned system failures. 3D printing has been in the spotlight as the market incorporates new and more sophisticated offerings sporting novel printing technologies and advanced materials choices. At the same time, this next-generation of high-powered printers has been retooled to fit the needs of mainstream design and manufacturing engineers, from a cost and accessibility standpoint. The result has been increased adoption of 3D printing for industrial-grade…

Found in Robotics News & Content, with a score of 12.49

…reality.” TensaBelt decided to invest in in-house 3D printing. “Additive manufacturing gives us a clear product evolution, as we are able to touch and feel each part while testing,” says Bazán, who adds that now they can “have a prototype in our hands in a matter of hours, instead of waiting on an external supplier for days.” By fabricating the different versions of each piece through 3D printing, the TensaBelt team can validate the volume, shape, joints, assembly and functionality of all mechanisms of their products. The possibility of fast iteration ensures plenty of chances to redevelop each model as…

Found in Robotics News & Content, with a score of 12.47

…printing into all avenues of its product development and manufacturing processes, Ford is pursuing a pilot project to jump-start the design of tools and fixtures, including making it easier for plant floor workers to produce components on their own without help from experienced experts. Ford’s Cologne, Germany, pilot plant maintains a small-scale manufacturing line, which develops cars years before they go into production. As part of their efforts, the team has been honing an optimized workflow to create jigs, tools and fixtures at local plants using 3D printing techniques as opposed to subbing out the components to external partners. Ford…

Found in Robotics News & Content, with a score of 12.44

…in the shortest amount of time, and the ever-evolving additive technology from Stratasys gives us confidence in our approach.” Team Penske and Stratasys have worked together through five championships and more than 70 race wins since their relationship started in 2017. In that time, Team Penske has gone from two Stratasys 3D printers to four. The company now has three FDM 3D printers supporting advanced materials—a Stratasys F900, Fortus 450mc and Stratasys F370—primarily for tooling, fixtures and end-use parts for cars. The team also has one PolyJet Technology-based J750 3D Printer for prototyping. All are installed at the Team Penske…

Found in Robotics News & Content, with a score of 12.34

Two startups, pioneering solutions in the additive manufacturing and blockchain technology arenas, are teaming up to offer an offering aimed at delivering trust to a new generation of on-demand spare parts produced as part of a digital supply chain. Data Gumbo, the provider of the GumboNet massively interconnected blockchain network, is working on a pilot project with Fieldmade, an Oslo, Norway-based company aiming to empower next-generation supply chains with on-demand production of spare parts using AM capabilities. Together, the partners are trying to shake up the way aerospace and defense and oil & gas supply chains have operated for the…