Editors’ Picks

Found in Robotics News & Content, with a score of 13.35

…about 135 employees. Source: Piab Group IB adds custom, additive manufacturing expertise IB Verfahrens- und Anlagentechnik said it has developed customer-specific, turnkey systems for handling bulk materials since 2007. The Lage, Germany-based company added that it has about 30 employees and decades of experience in conveyor technology for conventional materials handling. “Together with Piab Group—who is known as a world market leader in vacuum transport solutions—a strong team comes into being for a strong future,” said Frank Scholz, owner and managing director of IB. “We are convinced that both companies will profit from this acquisition and look forward to our…

Found in Robotics News & Content, with a score of 13.33

Manufacturing is changing. Never mind the remarkable utility of 3D scanning, the customization capability of additive manufacturing, or the facile methods of rapid prototyping—there’s a whole new way of using cloud computing to disseminate design information instantly. Potentially, it provides a new chapter in the way we manufacture everything. Welcome to contract manufacturing—also known as manufacturing as a service (MaaS). “For decades now, companies have shifted from vertically integrated design, engineering and manufacturing, to relying on external contract manufacturing partners,” says Andrew Edman, industry manager for product design, engineering, and manufacturing at Formlabs in Somerville, Mass. “Even manufacturers that continue…

Found in Robotics News & Content, with a score of 13.30

…completed a collaboration to evaluate the automation of crucial manufacturing operations using the global aerospace company’s industrial robots integrated with Xaba’s proprietary physics-informed deep artificial neural network model, xCognition. Xaba and Lockheed Martin identified a use case focused on a typical robotics work cell used in any aerospace factory to test how Xaba’s xCognition “synthetic brain” could empower a commercial robot with greater intelligence and understanding of its body and the task it is about to execute while ensuring required quality and tolerances are achieved. The test consisted of two phases: Phase 1: Assessing the robot’s performance in maintaining accurate…

Found in Robotics News & Content, with a score of 13.26

…produced using BigRep's technologies. Image courtesy of JAMADE/BigRep. Large-scale additive manufacturing (AM), and the BigRep One printer in particular, fit the bill because they deliver cost efficiencies along with better accuracy and quality compared to the high investment associated with traditional tooling, JAMADE founders maintain. That’s especially important in light of the company’s expectations for modest sales in Amazea’s first year as marketing and distribution efforts ramp up and customer demand builds. Just as JAMADE charts new waters with its manufacturing approach, other companies in industries like aerospace and automotive are beginning to see value in trading up traditional manufacturing…

Found in Robotics News & Content, with a score of 13.11

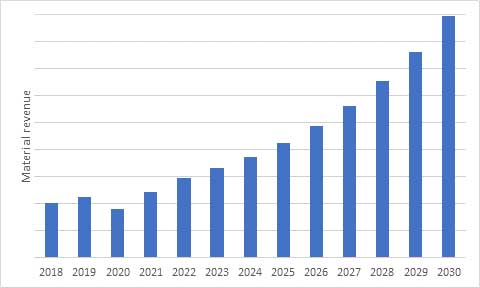

3D printing offers a means to improve current manufacturing limits across economic sectors such as transport, construction, and medical and dental industries allowing rapid prototyping and on-site production and repairs, according to IDTechEx. Progress in 3D printer development has led to faster, larger and more accurate printers, but these require more functional materials, IDTechEx adds. The company has released a new report, “3D Printed Materials Market 2020-2030: COVID Edition.” 3D printing use in the medical industry is restricted by the lack of biocompatible and biodegradable materials suitable for the 3D printing of medical devices with silicone-like mechanical properties. Korean researchers…

Found in Robotics News & Content, with a score of 13.05

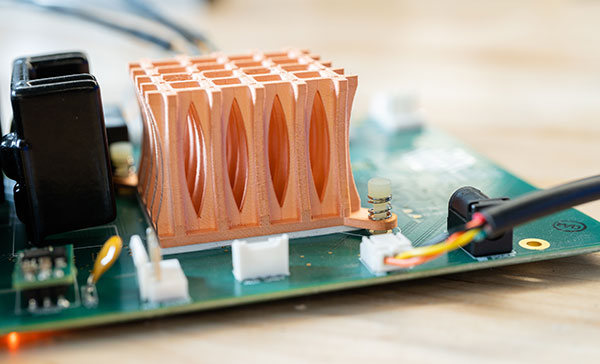

…3D printing copper parts on demand will drive new manufacturing and supply chain efficiencies for customers, leading to reduced lead times and part costs, as well as eliminating the need for costly inventory. Available today, Markforged provides an easy and fast way to produce geometrically complex copper with high electrical and thermal conductivity. “Copper powers our world. It’s everywhere. It builds our cars, enables phones, and keeps electrical equipment running,” says Greg Mark, Markforged CEO and founder. “Copper has traditionally been an expensive and challenging material to machine and incompatible for 3D printing in a pure form with other techniques.…

Found in Robotics News & Content, with a score of 13.01

…required in production. Leading automotive manufacturers are relying on additive manufacturing (AM) to accelerate the product development cycle and also to reduce resources such as time and energy. AM is already transforming automotive production workflows, impacting R&D, supply chains and production. Iterative Research and Development AM has revolutionized R&D for vehicle manufacturers—increasingly being used to reduce development times, improve prototyping workflows and deliver innovative parts that would not be possible using traditional techniques. Light covers are just one example of 3D printed vehicle parts. Image courtesy of 3D Systems. In several major U.S. auto manufacturers, 80% to 90% of each…

Found in Robotics News & Content, with a score of 12.96

…Components & Products Implementing Simulation Governance & Democratization Advancing Manufacturing Processes & Additive Manufacturing Addressing Business Strategies & Challenges The final conference schedule is due to be announced in February, but NAFEMS has already lined up an impressive group of keynote speakers. They include: Geoffrey Moore, consultant and author of Crossing the Chasm. Amir Husain, inventor and author of “The Sentient Machine”, as well as the CEO of AI company SparkCognition. Dr. Maria Klawe, president of Harvey Mudd College, who will discuss increasing diversity in the STEM workforce. Monica Schnitger, president and principal analyst at Schnitger Corp. and occasional DE…

Found in Robotics News & Content, with a score of 12.94

As the director of the Center for Advanced Manufacturing for the Massachusetts Technology Collaborative, Christine Nolan has seen firsthand the work being done throughout the commonwealth to bolster local industries. Created by the state legislature in 1982, the Massachusetts Technology Collaborative is a state public economic development agency that supports industries throughout Massachusetts through grant funding and programming. The collaborative is made up of five parts that focus on specific divisions, including broadband, cybersecurity, digital health, innovation, and manufacturing. Nolan’s agency gives grant funding to companies and universities working on projects aimed at creating jobs and advancing manufacturing. “We care…

Found in Robotics News & Content, with a score of 12.87

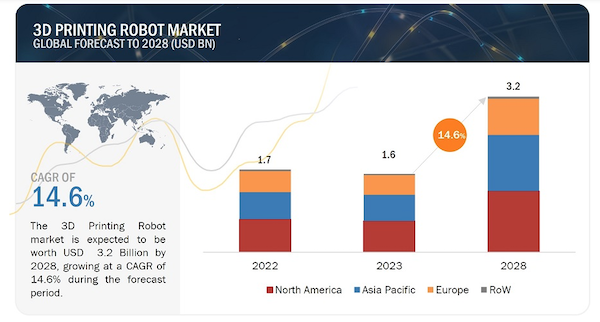

…or extruders, present a host of valuable advantages for additive manufacturing. These heads are versatile, capable of accommodating a broad spectrum of materials, from PLA (polylactic acid), PETG (polyethylene terephthalate glycol), TPU (thermoplastic polyurethane), and ABS (acrylonitrile butadiene styrene) to metals, enabling their application across diverse industries. Renowned for their precision, 3D printing heads can meticulously create objects in the X, Y, and Z axes, resulting in highly accurate prints with exceptional surface quality. Additionally, their ability to operate at high speeds contributes to shorter production times. Furthermore, these heads exhibit efficiency by judiciously utilizing filament material through controlled deposition.…

Found in Robotics News & Content, with a score of 12.84

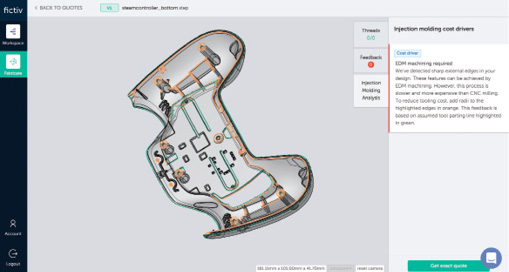

…pioneered by tech disruptors such as Airbnb, applied to manufacturing. Airbnb matches those seeking short-term living accommodations with those who happen to have extra space that can accommodate travelers. Thus, a whole new ecommerce infrastructure was born to satisfy the backpackers and budget-conscious travelers who previously didn’t have an option; and the homeowners who previously didn’t have a good way to offer their extra bedrooms and vacation homes for rental. Similarly, manufacturers with extra production capacity can join the Fictiv and Xometry networks, where they could be discovered by inventors, hobbyists and small startups with low-volume orders. But what makes…

Found in Robotics News & Content, with a score of 12.84

FANUC America Corp. and the Manufacturing Skill Standards Council (MSSC) yesterday announced that they have decided to co-market the stackability of their respective industry-recognized certifications to help meet the acute shortage of skilled industrial robotics and automation operators. “The collaboration between FANUC and MSSC will provide a major benefit to employers looking to fill Industry 4.0 robotics and CNC technical positions,” said Paul Aiello, director of the CERT Education Group at FANUC America. “The entire manufacturing industry in the U.S. is facing a growing shortage of higher-skilled technicians vitally needed at the operator level.” “We look forward to incorporating the…