Editors’ Picks

Found in Robotics News & Content, with a score of 15.36

…its service robot portfolio. It now consists of the Vacuum 40, Scrubber 50, Scrubber 75, and Sweeper 111 systems. By 2021, the cleaning robots were deployed in over 40 countries across six continents, according to Gausium. The company said it has thousands of satisfied customers, with millions of autonomous operational hours accrued and billions of square meters covered. Gausium said its X1 and the Scrubber 50 Pro (S50) are its first two products designed to support companies struggling with labor shortages or transforming how work is done. Following the successful commercialization of its Whiz autonomous vacuum cleaner, SoftBank Robotics said…

Found in Robotics News & Content, with a score of 15.32

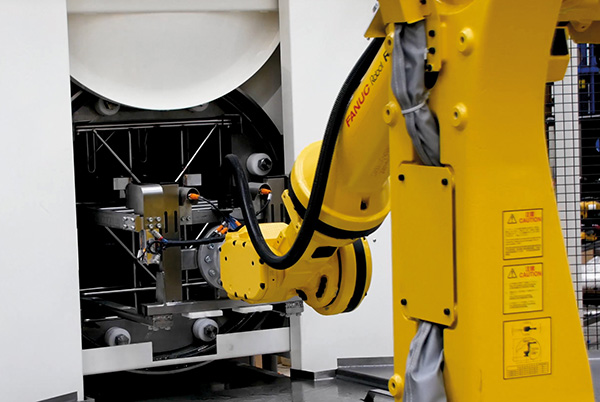

…according to Ultraseal International. One automotive manufacturer used robotic vacuum impregnation to seal porosity, minimize scrappage, and increase throughput, while also significantly reducing costs, explained Bob Remler, technical sales manager in North America for the Coventry, U.K.-based company. Trends and challenges Demand for die casting is on the rise, with the market projected to grow to $94.1 billion (U.S.) by 2025. In the U.S., the automotive industry is a major user of die casting, with a high proportion of components—including cylinder heads, engine blocks, transmission cases, electric-motor housings, and structural parts—produced using high-pressure, die-casting processes. With an increasing focus on…

Found in Robotics News & Content, with a score of 15.13

…integrator, AWL works together with various suppliers of robots, vacuum technology, and vision software, among other things. By integrating the artificial intelligence-based vision software of Fizyr into machines, AWL makes automated picking in harsh logistics environments possible. “You cannot accomplish anything alone; you will need others,” says Brand van ‘t Hof, CEO of AWL. “You can achieve something through collaboration.This applies to the corporation between robots and the vision software of Fizyr. AWL takes care of the integration. Not just for today’s solutions, but the solutions for the future.” AWL uses its picking competencies for the postal and parcel industry…

Found in Robotics News & Content, with a score of 14.42

…equipped with a dual disk scrub path, a high-performance vacuum system, and lithium-ion batteries for up to two and a half hours of runtime on a full charge. Source: Tennant Company Engineered from the ground up for autonomous operation, Tennant said the X4 ROVR robotic scrubber delivers unparalleled cleaning performance and adaptability across numerous commercial environments, including retail, healthcare, education, as well as multiple building service contractor (BSC) applications where optimized productivity is crucial to success. “The new X4 ROVR robotic scrubber has been meticulously developed to help cleaning teams free up bandwidth and, as a result, improve their efficiency,”…

Found in Robotics News & Content, with a score of 14.21

…used to quickly produce equipment like braces, clamps and vacuum pumps at remote hospitals in Kenya. The founders learned, however, that a bigger pain point was the lack of access to CAD files, so they have developed a cloud-based system that provides hospitals with access to files along with training on how to 3D print parts. “Our customers are healthcare facilities that don’t have access to the supply chains they need and over 40% don’t have the equipment needed to treat their patients. We bring the ability to locally manufacture what they need, when they need it. That is a…

Found in Robotics News & Content, with a score of 14.09

…the grocery segment.” Plus One Robotics announced a new vacuum gripper with individualized cup control to improve parcel slection and handling. Source: Plus One Robotics Individual Cup Control Gripper optimizes parcel singulation Plus One Robotics also introduced a new gripper design for parcel induction. The company’s Individual Cup Control Gripper leverages the AI of Plus One’s PickOne vision software to grasp and singulate parcels using the optimal configuration of active suction cups. Plus One said individual cup control offers several operational benefits: Minimize unintentional multiple picks: the combination of cup configurations enabled by this design allows the gripper to match…

Found in Robotics News & Content, with a score of 13.68

…by humans that is now being widely automated. Roomba vacuums are one of the most basic versions of a cleaning robot, allowing users to vacuum their home with a few taps on a smartphone app- but now these machines are evolving to do more than simply pick up crumbs. Automation for medicine Healthcare workers have been through a lot in the past few years: stress, burnout, and long shifts to compensate for labor shortages. The value of AMRs in healthcare was confirmed during the pandemic in infectious disease units by limiting the hospital staff’s contact with pathogens to ensure staff…

Found in Robotics News & Content, with a score of 13.55

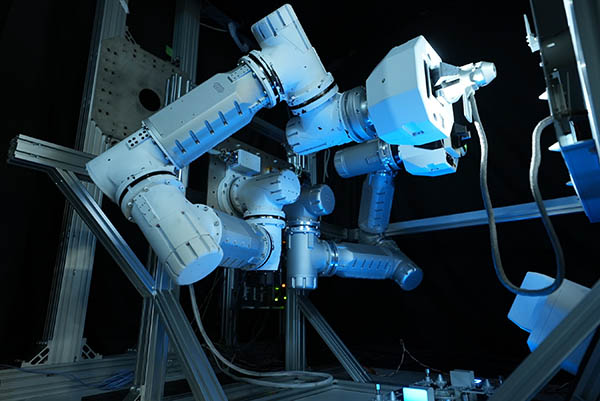

…autonomously execute in-space servicing, assembly, and manufacturing in the vacuum of space. The arm was delivered last August via a SpaceX capsule. The company tested this same model in the Japanese Aerospace Exploration Agency's (JAXA) 8 m (26.2 ft.)-class thermal vacuum chamber in February. The robot then reached NASA's Technology Readiness Level (TRL) 6 following this ground system test. GITAI said it expects to achieve TRL Level 7, confirming of its feasibility as a system in space. The company said it will then further develop the robot's in-space capabilities with the goal of providing it to private U.S. space stations…

Found in Robotics News & Content, with a score of 13.20

…rails to further increase production flexibility and throughput capacity. Vacuum cups and other wear items on each existing robot’s end-of-arm tooling were refurbished and existing conveyor was also expanded and relocated. Existing tape inspection stations were relocated and fitted with new technology, and four new random case tapers were added to ensure tape is properly applied to the top and bottom of each case. Bar code scanners were updated with the latest technology to improve reliability and reduce cost to route cases from production to more than 100 SKU locations along the robotic unitizing lines. “Overall, the biggest benefit from…

Found in Robotics News & Content, with a score of 12.14

…Ecobot product line from Gaussian Robotics includes a robotic vacuum and sweeper, as well as scrubbers and sprayers. The company claimed that its systems have cleaned more than 150 million km (93.2 million mi., the distance from the Earth to the Sun). The Scrubber50 requires only two hours of maintenance for every 100 hours of autonomous operation, said Gaussian. By contrast, a manually operated scrubber requires 15 hours of downtime per 130 hours of operation, it added. Gaussian is collaborating with Singapore-based Integrated Facilities Services Consulting Pte. Ltd. (IFSC), which said it uses data-driven optimization heuistics to provide continuous insights…

Found in Robotics News & Content, with a score of 11.77

…the wheels and reducing risks of clogs in the vacuum hose and tank. The Bulk Navigator utilizes advanced localization algorithms, allowing the robot to clean in the most dynamic and challenging environments. Advanced Obstacle Detection identifies and avoids obstacles on the floor including pallets and forklift/pallet mover tines through machine learning capabilities. “Neo 2W is the result of extensive involvement from customers based on their experiences using autonomous robots in warehouse settings. Avidbots gathered feedback, tested prototypes in real-life scenarios and utilized this data to deliver a truly purpose-built robot,” he said. “Given this robust process, we’re able to deliver…

Found in Robotics News & Content, with a score of 11.71

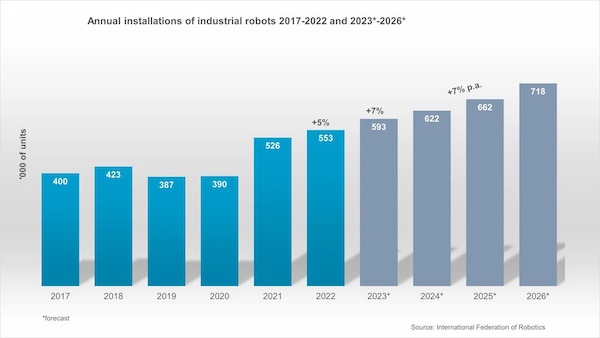

…more consumers enjoy the convenience of having a robot vacuum their home or take care of the lawn, it is in industrial applications that robotics have made the biggest impact. State-of-the-art manufacturing processes are unthinkable without industrial robots handling part of the workload, whether it’s handling, welding, or assembling, which are the three most common applications of newly installed industrial robots in 2022. Based on data from the International Robotics Federation (IFR), the operational stock of industrial robots has tripled over the past decade, with almost four million robots in use across various industries by the end of 2022. According…