Editors’ Picks

Found in Robotics News & Content, with a score of 8.33

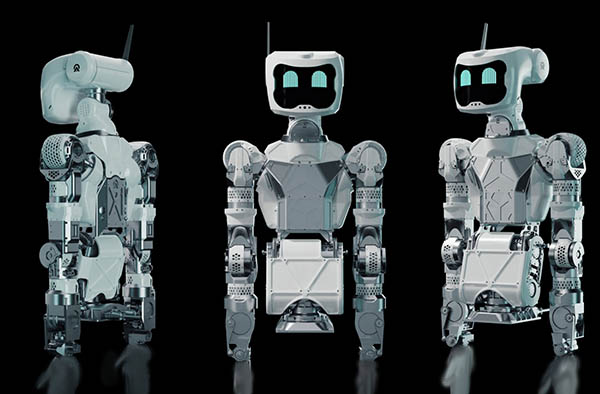

…matter is that we don't require nearly the same precision of classic industrial robots. Our applications require orders of magnitude less precision compared to industrial robots. This allows us to architect the robots in an entirely different way. We believe that we can build a dual-arm system for less than the price of a single-arm classic industrial robot. A full humanoid shouldn’t cost more than the price of a car as we get to scale. That is our commitment, and we are using everything we have learned to get there. When do you expect to commercialize the product? Cardenas: We…

Found in Robotics News & Content, with a score of 8.33

…that augment human intellect with the strength, endurance, and precision of machines to enhance employee safety and productivity. Sarcos serves the construction, defense, logistics, and utilities industries. Based on more than 30 years of research and development, the company's systems include the Guardian S inspection robot, the Guardian GT mobile manipulator, the Guardian XO full-body industrial exoskeleton, and the Guardian XT teleoperated avatar. In October, Sarcos won a U.S. Navy contract to expand testing of its Guardian DX single-armed teleoperated robot. Guardian XT Sarcos said its Guardian XT is a dual-armed robot designed to perform tasks with human-like dexterity while…

Found in Robotics News & Content, with a score of 8.31

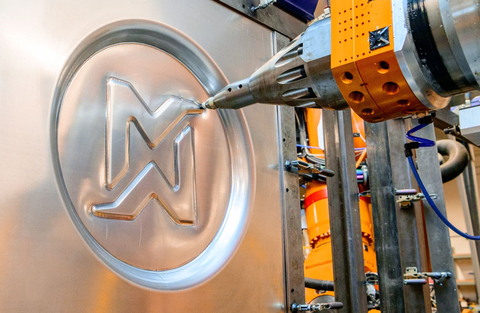

…and more – require high levels of quality and precision at bespoke product volumes,” said Anish Patel, COO and managing director at Yamaha Motor Ventures. “For this reason among others, our investment in Machina Labs is an ideal fit. Their ability to rapidly iterate, improve, and manufacture metallurgic products increase our speed of innovation.” “With an addressable market in the billions, we’re excited to play a role in Machina’s success,” Patel said. “If you can imagine a metal part, there’s a very good chance we will be able to build it using our innovative combination of dieless sheet metal sheet…

Found in Robotics News & Content, with a score of 8.30

…operation. “Cobots augment and enhance a fabricator’s capabilities with precision, repeatability, and tireless performance, freeing employees from tedious, repetitive activities so that they can provide more value to the organization in other roles,” said Zac Bogart, president of Productive Robotics. “Because we have removed the need to program OB7, any employee can show the cobot what to do by walking it through the steps of a task,” he said. “The teach-by-touch design allows our cobots to learn jobs in just minutes.” Seventh axis of freedom allows for flexibility The cobots can be used for welding, gluing, deburring, material handling, packing,…

Found in Robotics News & Content, with a score of 8.28

…teeth and ensures smoothness of the movement, quietness, positioning precision equal to 0.4 mil/0.01 mm and easy and fast maintenance operations. The manufacturer’s choice of these components is fundamental to guarantee the best quality printing of high-temperature polymers like PEEK. “The ability to use custom filaments and control the print processing was a critical factor in selecting ROBOZE. The flexibility allowed by ROBOZE along with its excellent printing capabilities is well aligned with the discovery-oriented research mission of the university to expand knowledge and its application,” continues Vogt. Sources: Press materials received from the company and additional information gleaned from…

Found in Robotics News & Content, with a score of 8.27

…other in-house technologies. They not only bolster motion control precision, but also contribute to smooth and reliable operation. Embedded into each fingertip of the XHand are highly sensitive array sensors that collect and generate information including the size, shape, texture, softness and force feedback of the object being grasped. The dexterous hand generates a maximum force of 80 neutrons and exceeds human capabilities in object grasping. With a high payload, it is designed to hold heavy items like a 5kg bottle of water and adapt to a variety of working environments. More importantly, the intricate inner mechanisms of the XHand…

Found in Robotics News & Content, with a score of 8.26

…Welding Head they developed for Hittech Bihca, supplier of precision components. Improved performance, functional integration, conformal cooling channels, light-weighting and optimized local porosities are all features of this application. An honorable mention went to Nina Uppenkamp from the SMS Group in Germany. Her redesigned Media Block design is a demonstration of a manifold that is optimized for metal additive manufacturing. The original part and the redesigned part were functionally tested and compared. All finalists get a free licence of Altair Inspire and Autodesk Netfabb software. Younes Chahid, as student winner, has won an Ultimaker 2+ printer while the team of…

Found in Robotics News & Content, with a score of 8.24

…manufacturing, driven by advanced technologies like AI, automation and precision engineering,” according to Advanced Navigation. “In the context of autonomous systems, the importance of precision and reliability is non-negotiable.” The facility at the University of Technology Sydney (UTS) Tech Lab follows a “vertical integration framework,” housing equipment for automated manufacturing using machine learning, according to the company. This “guarantees the delivery of reliable, durable, and high-quality navigation technology,” it said. The new facility will make systems including the Boreas digital fiber-optic gyroscope (DFOG). Advanced Navigation claimed that it is one of only four companies in the world with the capability…

Found in Robotics News & Content, with a score of 8.24

…of robotics,” said Fredrik Malmgren, CEO of Cognibotics. “Easy-to-use, high-precision robots form affordable, versatile tools that support and complement human capabilities for productivity and work quality. The HKM1800 represents a significant leap forward in automation capabilities, and we're excited to share our latest progress and its potential with the world.” The HKM1800 has several key features that the company says set it apart from traditional pick-and-place robots: Unmatched speed with exceptional reach: Unlike traditional industrial robots, gantry, SCARA or delta robots, the HKM1800 achieves an impressive pick rate of over 2000 articles per hour, making it the fastest robot currently…

Found in Robotics News & Content, with a score of 8.22

…Nicholas Fang in 2016 to improve the resolution and precision of 3D printing. Today, BMF is helping customers in the race toward ever smaller parts by offering new kinds of printers that are being used to make electronics, medical devices, microfluidic chips, and more. The company’s machines use a technology co-developed by Fang to print millimeter-sized products with details at the micron scale — objects you can see with the naked eye, but whose details you’ll likely have to squint to make out. The company says the printers enable the creation of new parts with tiny, complex geometries, and entirely…

Found in Robotics News & Content, with a score of 8.21

…100 locations in more than 53 countries. PixelPaint offers precision, sustainability Multi-colored car painting has traditionally been a laborious and costly process involving multiple stages of masking and unmasking. ABB said its PixelPaint technology “reimagines” the paint application process and reflects the growing demand for sustainable personalization in the automotive industry, particularly in exterior paint. PixelPaint allows for a detailed, colorful, and exact replication of any design, according to the company. Carefully controlled, the paint can be quickly applied in a single application. This advancement in automating the painting process could allow for specialized and personalized designs to the automotive…

Found in Robotics News & Content, with a score of 8.19

…humans performing the same tasks. In some cases, this precision can be measured at micron levels. This level of precision also translates to a reduction of raw material waste. “Cobots are more consistent than human workers at performing certain tasks, are flexible enough to be deployed in a wide range of applications, and are easily transported and deployed,” said Campbell. “These qualities provide cobot users with additional productivity boosts.” Furthermore, cobots can operate 24/7, shortening cycle times and supporting just-in-time manufacturing. Automation helps users adapt to market demands Another way cobots can help increase productivity is by providing companies with…