Editors’ Picks

Found in Robotics News & Content, with a score of 6.70

…machines is their compatibility with a wide range of plastics and metals. Robot components made with CNC machining Robot arms From large industrial automation to smaller and lighter collaborative robot arms, they are used in a wide range of industries. Applications for robot arms include moving objects and loading and unloading high-strength materials like aluminum, steel, and hard plastics. Robot arms made with CNC machines can be more more accurate and precise than those made using traditional processes. Jigs and fixtures Jigs and fixtures typically hold workpieces in specific positions while robots work on them, and numerous operations require custom…

Found in Robotics News & Content, with a score of 6.66

…of the micro-sized scale of some features in the plastic attachments for the 2-mm device. Traditionally, a company such as UVision360 would have had to build stainless steel tools for injection molding the complex parts. However, that process would have added several months to the prototyping process. The company turned to Protolabs’ micro-resolution SLA 3D printing process and MicroFine Green thermoset resin to build parts in 0.00-in. layers. “As a startup we have to make much tougher decisions on where to spend the money because we don’t have unlimited funds,” says Erich Dreyer, chief technology officer for UVision360. “So what…

Found in Robotics News & Content, with a score of 6.59

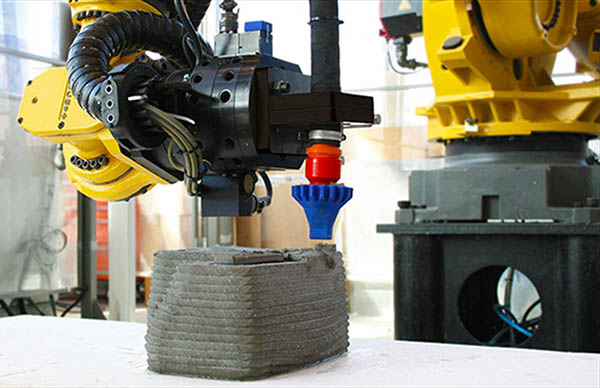

…due to the increase in materials. Historically, resin and plastics were at the forefront of 3D printing. However, metals have recently been introduced to the industry, which means even the most complex parts will no longer need to be shipped from warehouses far away. Instead, they’ll be printed in-house – thereby eliminating a lengthy supply chain. Let’s explore how the pioneers of 3D production in manufacturing: Electrolux, Ford, and Caterpillar, have continued to push the industry forward with innovations in materials, speed, and costs. Electrolux | 3D Print On Demand to Lower Costs As the company moves toward “smart factories”…

Found in Robotics News & Content, with a score of 6.57

…to the consortium, plan events, and further enhance capabilities. The partnership's stated goal is to eliminate packaging waste and plastic storage from most aspects of the supply chain and operations. “Sustainability ... means more profits for clients and measurable improvements for the environment,” said Chang Industrial. In addition to manufacturing, the consortium will target healthcare, food processing, consumer products, retail, and wholesale distribution, the partners said.

Found in Robotics News & Content, with a score of 6.50

…done the other way around. Layers of material, typically plastic, metal, or ceramic, are used to create these objects. It's highly effective for several reasons. “When you're using additive manufacturing, you'll see that it's often cheaper, especially for one-off builds,” said Jeanette Harrison, a business writer at Elite Assignment Help and OX Essays. “It's also ideal as it creates less waste and ensures you can get items on the market as fast as possible, while still ensuring quality.” 2. Choose the right solvent Once you start planning your 3D printing setup, you'll need to think about the materials that you'll…

Found in Robotics News & Content, with a score of 6.49

…for an order are present and ready for finishing, plastic totes are automatically conveyed from the mini-load to a robotic piece picking station where two robotic arms pick and place the right frames and lenses for a customer order onto a plastic tray that is then sent to a finishing station. It is a complex process that requires precise timing, but the software behind the solution makes it all appear deceptively simple. The technology allows VSP to start work on a pair of glasses as much as 24 hours earlier than in the past, shaving at least one day, or…

Found in Robotics News & Content, with a score of 6.44

…more than 100 parts, 50 of them unique and plastic, to continuously adjust the pressure of the drive motor on the tire in response to sensored slippage, which optimizes performance regardless of road or weather conditions, officials say. ShareRoller initially opted to outsource parts production, but found it repeatedly faced challenges with part strength and surface quality. There were also long lead times and minimum order requirements, which made it difficult to iterate designs and produce prototypes, Guida explains. In addition, there is enormous part diversity with the OneMotor as it’s designed to attach to any number of bikes and…

Found in Robotics News & Content, with a score of 6.39

…In the event of an incident like metal or plastic contamination, companies can browse their image library by timestamp and pinpoint the exact time an incident has occurred. This allows them to isolate the occurrence of an incident to a specific timeframe and inspect meals that may have been affected. As a result, Chef Robotics says Placement QA can save organizations from expenses associated with needing to throw out an entire production run’s worth of meals, and further reduce labor overhead as a direct result of reducing the number of employees needed to conduct spot checks. Typically, food facilities select…

Found in Robotics News & Content, with a score of 6.38

…of fossil fuels compared to conventional manufacturing technology. Redesigning plastics laser sintering Most of the announcements Materialise made at its recent annual conference (moved online like everything else these days) aim for the sustainability agenda. The first was Bluesint 12, a laser sintering specification that allows material reuse. Materialise says when residual powder from a previous 3D printing project is used, it creates an “orange peel” effect in which surface texture is “largely unusable.” Materialise says this orange peel effect is caused by “shrinking that occurs when the powder cools down between two consecutive sintering processes.” The existing solution is…

Found in Robotics News & Content, with a score of 6.35

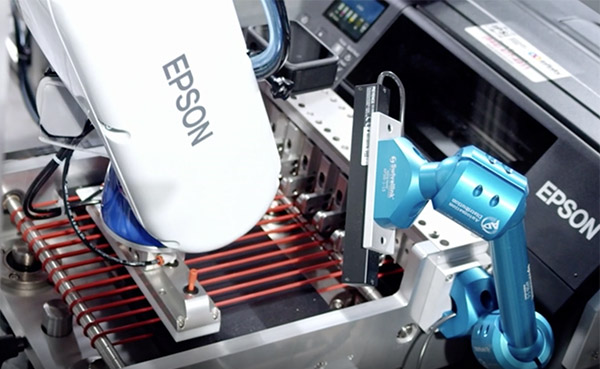

…assembly and material handling applications in the aerospace, appliance, automotive, biotechnology, consumer product, electronics, food processing, medical device, pharmaceutical, plastics, semiconductor, and telecommunication industries. Epson Robots is a unit of Epson Group, which is led by Tokyo-based Seiko Epson Corp. and said it generates annual sales of more than JPY 1 trillion ($6.8 billion U.S.). Los Alamitos, Calif.-based Epson America Inc. is the group's regional headquarters for the U.S., Canada, and Latin America. Editor's note: For more about PACK EXPO, visit Robotics 24/7's special coverage page.

Found in Robotics News & Content, with a score of 6.34

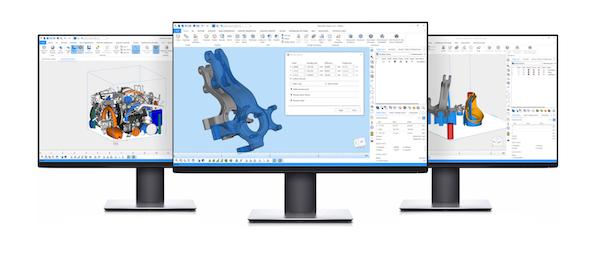

…Program,” a limited-time offer for premier metal and industrial plastic additive users. Built upon the company’s Accelerated Computation Engine (ACE), a GPU-powered geometry kernel, AMT provides manufacturing-oriented features. Capabilities include native CAD file import for maximum quality of 3D-printed output, as well as an integrated Python application programming interface (API) for customizable scripting of interactive, automated workflows. Dyndrite’s ACE geometry kernel and AMT build processor were designed from the ground up using a “First Principles” approach, leveraging modern methodologies and technologies to meet the requirements of production oriented customers in the aerospace, medical, automotive, energy and service bureau markets. Dyndrite…

Found in Robotics News & Content, with a score of 6.33

…said the flexible N-220 will help it expand into high-growth industry segments including metal, food and beverage, fulfillment, and plastics and chemicals. “We expect 160 to 220 kg payload articulated robots to represent an estimated 30% of the total installed market, composed of 250,000 to 300,000 units in 2022, with a potential compound annual growth rate [CAGR for] '22 to ’26 of 2%,” said Clement, citing a report by the International Federation of Robotics (IFR). Comau’s N-220 is now available worldwide.