Editors’ Picks

Found in Robotics News & Content, with a score of 10.69

…a sterile chamber around a 3D printer where unsterilized plastic is brought into the chamber. The possibly contaminated plastic is sterilized by the printing process and packaged maintaining the sterile field. This system was initially designed for a U.S. government agency to allow sterile medical materials to be printed at locations where commonly used sterilization methods might not be possible. “Because this printer can create sterile materials, which are sterile from the inside out once produced, we are eliminating the need for hospitals to resterilize equipment before use,” says Lacaze. “At a time when efficiency and supplies are critical, we…

Found in Robotics News & Content, with a score of 2.75

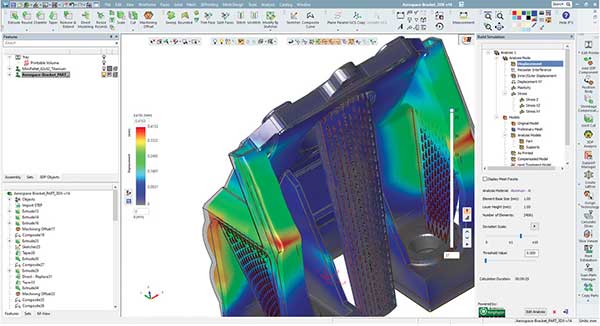

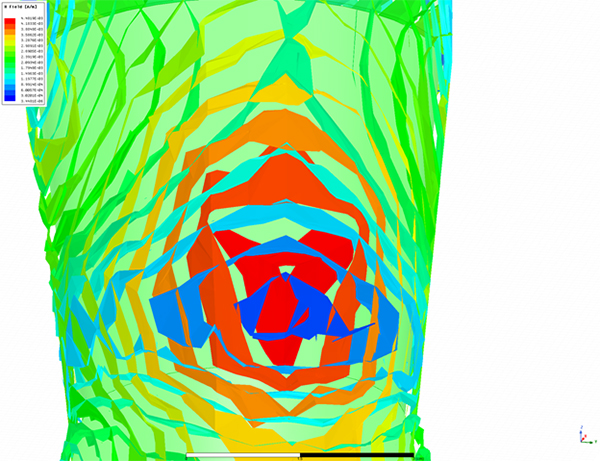

…advance. “There are more things you can do with plastic printing to compensate for the anticipated morphing or to fix it post-printing, but metal is much less forgiving,” Barkai says. “The harder the metal, the less forgiving it is. So printing in titanium, for example, gives you less room to work with than aluminum.” 3DXpert uses the Amphyon simulation kernel, developed by Additive Works. The same kernel is also used by Altair in its AM-targeted products. Described as “end-to-end fault prediction,” 3DXpert allows users to analyze and determine part orientation for the print job, design lattice fills and add support…

Found in Robotics News & Content, with a score of 23.51

…In response, UL has developed a certification program for plastics for additive manufacturing called Blue Card. According to UL, the Blue Card presents the data necessary to ensure the integrity and usefulness of materials intended for 3D printing and 3D printed components and products. A Blue Card is automatically issued when a material intended for 3D printing receives a UL Recognized Component Mark. UL Certified AM materials are published in UL's publicly available and searchable Product iQ database. As Blue Cards are specific to a 3D printer, a 3D printer manufacturer can also certify material for explicit use on his…

Found in Robotics News & Content, with a score of 4.16

…shields have FDM 3D printed frames, with clear, full-face plastic shielding,” the company writes in its dedicated page for COVID-19 response. To put its plan into action, the company is calling on 3D printing shops and service bureaus with volume-production capacity. It also has an online form for institutions to request shipments of easily assembled protective shields. 3D printer maker Stratasys organized a face shield production project. Shown here are student workers with printed shields. Image courtesy of Stratasys. Scaling Challenges with 3D Printing The face shields are the most immediate needs Stratasys plans to tackle, followed by face masks…

Found in Robotics News & Content, with a score of 8.14

…at 11 injection molding machines spent their days unloading plastic pallets and manually trimming and stacking them for transport to the warehouse using forklifts or pallet jacks. The repetitive and physical work at the 400,000-square-foot facility made it difficult to retain workers, while forklifts on the floor lead to safety concerns. A new fully automated production line including mobile robots (Mobile Industrial Robots, or MiR) has improved safety and productivity. To automate the process and improve safety, Cabka designed a fully automated production line. The new line includes a mobile robot and a six-axis robot to autonomously unload pallets from…

Found in Robotics News & Content, with a score of 10.85

…system is designed for order fulfillment and returns processing of items in poly-bags or self-sealing mailer bags. These malleable plastic bags have become the preferred packaging method in e-commerce due to the lower shipping costs versus cardboard boxes. Modex 2020 is scheduled to be held March 9-12 at Georgia’s World Congress Center in Atlanta. The tradeshow will showcase the latest manufacturing, distribution and supply chain solutions in the materials handling and logistics industry. Modern’s complete coverage of the show.

Found in Robotics News & Content, with a score of 8.22

…cones and roll-up belts. Currently distributing over 10,000 injected plastic units across all of southern Europe, the production team says it recognized that it needed a quick and efficient solution for functional validation that would allow the company to achieve better results in less time, reducing their products’ time to market while maintaining quality results. Prior to integrating 3D printing, the product design team at TensaBelt didn’t count on many functional prototypes of their designs before new pieces would be fabricated. “Before having our BCN3D Sigmax, we would mostly work in a digital design,” explains the company’s global production manager,…

Found in Robotics News & Content, with a score of 19.90

…(SAAM HT) machine will now offer BASF 3DPS’s ABS plastic, carbon fiber PET and recycled PET materials. Ultrafuse ABS is created from acrylonitrile, butadiene and styrene polymers. It has a strong, flexible and heat-resistant nature, according to the companies. It can be used for those looking to manufacture low-cost prototypes, or anyone who wants to create plastic products with ease. Ultrafuse PET CF15 from BASF 3DPS combines processability and low moisture uptake with strength and rigidity. With this PET material, users can 3D print new components that stay functional under high mechanical and thermal loads. It’s suited for the automotive…

Found in Robotics News & Content, with a score of 15.89

…Image courtesy of ANSYS and Sebastian Celis Sierra Deadly plastic bottles The first step to clear the landmines is to pinpoint their locations beneath the ground. It's a lot harder to detect modern landmines with conventional radar because they are often housed in plastic containers. This is certainly the case with many landmines left in Cambodia. “Rebels fashioned them with whatever materials they happened to have on hand, including PVC pipes, plastic bottles, and various chemicals. They purposefully left metal out to prevent the military from identifying them with metal detectors,” according to a NOVA report from 2018. Sebastian and…

Found in Robotics News & Content, with a score of 35.53

…their flagship line for industrial 3D printing of ultra-high-performance plastics. The AON-M2 2020 is a high-temperature printer designed to work with a wide variety of plastics including several ultra-high-performance open standards materials. It also works with carbon fiber-filled variants. The AON-M2 2020 was designed for part accuracy and repeatability, as well as reliability in industrial settings. The chamber is all stainless steel with minimal thermal expansion, built around a new convective flow path. The unit can be ready for first print in less than 15 minutes, running at a constant 135℃ chamber temperature. Dual independent tool heads allow the user…

Found in Robotics News & Content, with a score of 37.25

…the machine manufacturers surrounding potential synergy between their respective plastics processing technologies. In a joint press release, the companies said it became clear that the range of products and services offered by each to the market was complementary, citing the “flexible and dynamic nature” of the Feldkirchen-based startup as key to the acquisition. The new owners have confirmed German RepRap will continue to operate as a separate start-up. The company's 23 employees in Feldkirchen are said to be unaffected and founder and Managing Director Florian Bautz will stay on board to run the business. Following the takeover, Arburg will work…

Found in Robotics News & Content, with a score of 16.98

The Pennsylvania State University, a 3D printing institution that operates the Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D), has increased its capabilities for advances in 3D printing by choosing a new FFF solution, ROBOZE One+400 Xtreme. CIMP-3D includes several additive manufacturing (AM) systems as well as a design studio and prototyping laboratory. Current research activity within the center is directed at the development of technologies that will enable greater use of additive manufacturing in industry. The ROBOZE One+400 Xtreme will be located within Penn State’s Department of Chemical Engineering. The new 3D printer is specifically designed to…