Editors’ Picks

Found in Robotics News & Content, with a score of 36.34

…designed to help fulfill the global demand for expert welding professionals, the companies said. Successful completion of the course leads to the acquisition of Comau’s Robotics Welding License. Industry 4.0 automation is increasing the level of skills required by welding professionals, yet robotic welding training is seldom offered at traditional welding training institutions or vocational training centers, the companies argued. Furthermore, a standardized robotic welding training curriculum does not currently exist. Traditional welding training and practice is also costly, time-consuming, and requires dedicated safety equipment. Training made with the Soldamatic welding simulator To meet these challenges, Comau and Seabery now…

Found in Robotics News & Content, with a score of 12.76

…of robot arm tools, including grippers, collision sensors, and welding torches. Materials handling is a big market for EOAT The EOAT market is estimated to increase by $892 million between 2020 and 2025, according to the report “Robotics End-Of-Arm Tooling Market by Application and Geography—Forecast and Analysis 2021-2025” from market research firm Technavio. “Manufacturers have been increasing their investments in industrial robots for assisting in a varied range of activities that human workers or alternative systems are performing,” said the report. “For achieving this, various end-user industries are increasing the adoption of EOAT which can handle multiple sizes, geometries, materials…

Found in Robotics News & Content, with a score of 9.38

…Picking Gets Faster With Robotic Perception Machine Tending and Welding With Robots More information about the sessions can be found at the event site. Unlike other robotics event, the first Robot Applications Conference will focus on robotics applications rather than individual technologies or market verticals. Speakers interested in participating in Robotics 24/7’s event can submit applications here. Please note that we are looking to speak to end users, analysts, and systems integrators. An attendee registration form will be up soon. Companies can learn more about sponsorship opportunities by contacting Tom Cooney at [email protected]. About Peerless Media Founded in 2010, Peerless…

Found in Robotics News & Content, with a score of 8.38

…been kept. While in one sector alone, the American Welding Society says the US will face a shortage of 400,000 welders by 2024. ABB’s study also found that American companies are relying more on automation to solve their supply chain woes. 43% of businesses surveyed indicated that they will use automation and robotics to build supply chain resilience, with 75% of US-based businesses noting that robotics and automation will play a significant role in addressing supply chain issues. Europe bullish on robotics Although there is a greater demand for robotics in the United States, ABB’s survey found that the rate…

Found in Robotics News & Content, with a score of 14.47

…applications are vast, ranging from materials handling, quality inspection, welding, and even food preparation and serving. In 2020, the global collaborative robot market was sized at $668 million, according to Mordor Intelligence. It is expected to reach $1.8 billion by 2026, according to the research firm. Future Market Insights estimated that the market will reach about $1.7 billion by the end of 2022. And by 2029, it will have a valuation of $8.6 billion. There are still limitations on what cobots can do in terms of payload weight, speed, and range. But cobot manufacturers are continuing to release cobots aimed…

Found in Robotics News & Content, with a score of 6.73

…it is suitable for machine tending, materials handling, and welding in addition to palletizing,” Beck explained. “We also designed a wider tool flange for the corresponding end effectors.” Universal Robots reaches for new applications Povlsen noted that global labor and skills shortages, as well as an estimated 22 million jobs with automatable tasks present a “real opportunity” for cobots, with only 2% penetration of the potential market. The UR20 will complement the existing e-Series cobots, and simulation tools are coming, according to Universal Robots. Potential users of the UR20 with UR+ certified URCaps applications include the automotive, food and beverage,…

Found in Robotics News & Content, with a score of 12.63

…its new high-end SCARA line. Yaskawa displayed its cobot welding work table. FANUC’s booth included its new food-picking delta robot, along with the large FANUC 1000iA assembly robot. Other companies, such as Universal Robots, showcased technologies that are still a little ways off. The Odense, Denmark-based company displayed a concept cobot that had a smooth exterior that could work well in food handling and medical environments. The company said it is showcasing the concept now to get customer feedback. Check out the slide show on the right (bottom on mobile) for a deeper look at some of the most interesting…

Found in Robotics News & Content, with a score of 7.90

…and leads its business development and application engineering teams. He has over a decade of experience in under-the-hood robotic welding and applications experience, which has given him both the passion and the know-how to help manufacturers identify how to improve weld processes with automation. Moderator: Eugene Demaitre Editorial director Robotics 24/7, Peerless Media LLC Demaitre is editorial director of Robotics 24/7. Prior to joining Peerless Media, he was a senior editor at other robotics publications. Demaitre has decades of experience in business-to-business, online technology coverage and has participated in numerous robotics-related webinars, podcasts, and conferences worldwide.

Found in Robotics News & Content, with a score of 4.96

…axis. The robolink can be used in pick-and-place, palletization, welding, and testing applications. It has also proved effective in cucumber harvesting, even in the dirty field environment. The unit also includes a special camera system that helps the robot detect and locate the cucumbers. The Fraunhofer Institute said the robot can locate approximately 95% of the cucumbers. “It is a considerable challenge to design autonomous systems capable of optical and tactile sensing, assessing, and evaluating,” the institute noted. “Cucumbers are randomly distributed through a field, and some are concealed by vegetation. Varying light conditions make the mission all the more…

Found in Robotics News & Content, with a score of 26.21

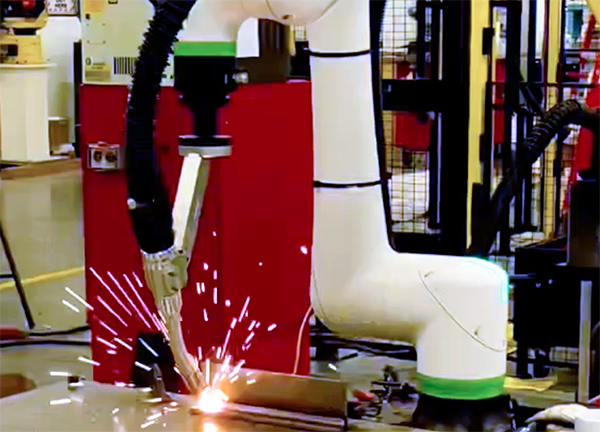

…to higher-return jobs instead of using them for simpler welding tasks, according to Acieta. The company said at Automate 2022 here that fabricators and job shops can now give the easier, low-value weld jobs to its new FastARC CX1000 collaborative robot. “The FastARC CX1000 repeatedly welds accurate and high-quality welds all day, every day,” said Bill Brauer, senior robotic systems engineer at Acieta. “That means less scrap, increased uptime, and greater capacity, so shops can take on more work.” Acieta, which exhibited at Booth 1807 at Automate, said it has been a robotics industry leader for nearly 40 years. It…

Found in Robotics News & Content, with a score of 7.90

…specifically screwdriving, with Tool House; machine tending with Ellison; welding with MRO; and pick and place and palletizing with Tool House and RG. The company also showed 3D scanning for automotive inspection with Korean partner Hexagon Metrology. In a grinding and polishing demo, Doosan showed how a user could tilt a smartphone to control the angle of a robot. Designing a future with more robots Beyond its Automate exhibits, Doosan Robotics is working on more software-driven capabilities. It works with the Robot Operating System (ROS). The company said it is building on its suite with a platform and integrated development…

Found in Robotics News & Content, with a score of 17.16

…Convention Center here from June 6 to 9. The spot-welding cell displays the combined power of Kawasaki Robotics' KRNX open programming platform and Realtime Robotics’ motion-planning and collision-avoidance software, integrated with two Kawasaki BX100N robots. KRNX is an application programming interface (API) plugin that enables real-time control (RTC) by advanced users to execute complex and irregular applications. Realtime said KRNX allows Kawasaki robots to use unlimited external computing power, enabling anything from AI and machine learning applications to advanced safety. A deeper look at Kawasaki's demo Two Kawasaki BX100N robots will simulate the welding of a car door using ARO…