Editors’ Picks

Found in Robotics News & Content, with a score of 10.61

…to perform demanding tasks such as machine maintenance and welding. It can also handle multiple devices simultaneously. The CS620's high trajectory accuracy and wide reach, which ensures that large components can be smoothly welded without using an external axis, said the company. Like all other models in the CS series, the CS620 robotic arm features an IP65 degree of protection, upgradeable to IP68. Rated for ISO Class 5 cleanrooms, the CS Series is suitable for industries that require the highest level of hygiene, such as pharmaceutical and electronics. Elite Robots said it will premiere the CS620 in the U.S. in…

Found in Robotics News & Content, with a score of 10.52

…of applications, the biggest increases were realized in spot welding (31%), assembly (15%), and material handling (6%). “As the technology behind robots is evolving, the number of tasks they are able to perform is increasing,” Burnstein said. “Today more than ever, robots can handle complex tasks at fast speeds, leading to high productivity for customers. Disruptive innovations like collaborative robots are helping to drive adoption of robotics in new and exciting ways, and that is promising for the future of our industry.” Burnstein noted that the RIA and its sister group AIA – Advancing Vision + Imaging, are seeing the…

Found in Robotics News & Content, with a score of 10.34

…people and businesses in the field of robotics, engineering, welding technique, and software development.” The proprietary MX3D printing technology uses off-the-shelf welding robots to build up metal objects layer by layer. The bridge design was created using generative design and topology optimisation techniques, which MX3D said allowed for design freedom and promised significant material reduction. “The unique design of the bridge would not be possible without 3-D printing,” said Stijn Joosten, a structural engineer at Arup. “Figuring out the structural properties of 3D-printed steel is an essential step for the creation of architectural projects using digital tools. Printed steel behaves…

Found in Robotics News & Content, with a score of 10.32

…components, but the main jobs of robots are still welding chassis and moving heavy parts. We also have battery production, which is something where robots are crucial.” The operational stock of robots has increased by 10% since 2019, and it experienced a compound annual growth rate (CAGR) of 9% from 2015 to 2020, said Müller. “The level of installations has been climbing over the past decade,” he said. “There was slowed growth in electrical, but increases nearly everywhere else.” Source: International Federation of Robotics The IFR's 350-page World Robotics 2021 reports for industrial robots and service robots can be ordered…

Found in Robotics News & Content, with a score of 10.29

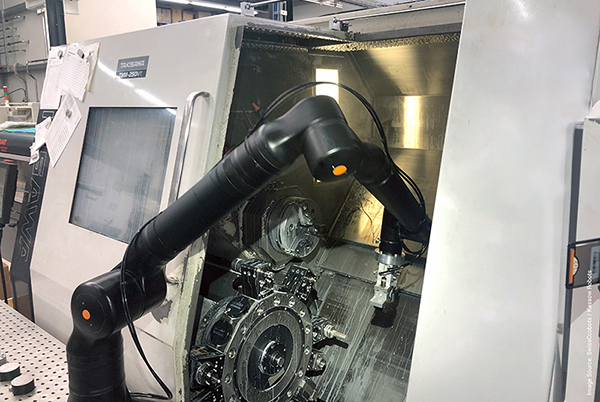

…president of solutions at GXO Logistics Machine Tending and Welding With Cobots: Josh Pawley, founding partner at Vectis Automation, and Brian Havey, director of sales at VersaBuilt Robotics Piece Picking Gets Faster With Robotic Perception: Sandeep Sakharkar, CIO of GXO Logistics Other sessions include “Palletizing and the Next Frontiers for Mobile Robots.” More speakers will be announced soon, and qualified experts can still apply to participate. Register now for the Robotics Applications Conference The Robotics Applications Conference is free, and registration is now open for all sessions. Visit Robotics 24/7 for the latest news about the commercial robotics ecosystem and…

Found in Robotics News & Content, with a score of 10.27

…robot's seventh axis, or “wrist joint,” enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said the company. The seventh axis also gives the KR1805 a small footprint of 160 x 160 mm (6.2 x 6.2 in.). This provides “a huge advantage in maneuverability” and an increased range of motion for tasks such as bin picking, packaging tasks, and labeling, asserted Kassow. The safety-compliant design allows the KR1805 to share a workspace with humans following a safety evaluation of the site where the system will be implemented, the company noted.…

Found in Robotics News & Content, with a score of 10.25

…continues to grow in the wake of digitization. Whether welding, painting, soldering, or palletizing, industrial robots work dynamically. A flexible multi-axis dress pack such as triflex® R from igus makes it possible to guide and secure cables and hoses used on multi-axis robots. igus has developed the i.Sense TR.B, a real-time breakage monitoring system for the multi-dimensional triflex R robotic dress pack to detect potential chain breaks due to extreme loads and avoid unplanned machine breakdowns. Smart real-time condition monitoring With i.Sense TR.B, customers can increase the safety of their robot systems with an investment of just a few hundred…

Found in Robotics News & Content, with a score of 10.20

…temperatures ranging from sub-zero to 1300°F. It also has welding characteristics, and is often used for high-temperature applications, such as jet engines and tooling, or corrosive environments, such as those featuring seawater or acids. “Today’s qualification of Inconel 718, following on the heels of M2 Tool Steel earlier this year, shows the ExOne R&D team is aggressively delivering new materials for binder jet 3D printing,” says Rick Lucas, ExOne CTO and VP, New Markets. “Our increasing pace of material qualifications is a testament to the strength of our new metal 3D printer systems equipped with Triple ACT, an advanced compaction…

Found in Robotics News & Content, with a score of 10.05

…the collaborative robots' seventh axis enables continuous dispensing, packaging, welding, bin picking, and material removal, regardless of access angle, without the need to reorient the arm, according to Kassow. When combined with simple programming techniques, the company said its cobots can help customers and integrators quickly and cost-efficiently automate complex tasks in material handling and other industrial applications. Kassow to debut at Automate Kassow Robots will be exhibiting its flexible cobots at Booth 1452 at Automate 2022 in Detroit from June 6 to 9. The Association for Advancing Automation (A3), which organizes the event, described it as “the largest solutions-based…

Found in Robotics News & Content, with a score of 10.00

…of body parts for the F-35 combat aircraft, arc welding of cruise ships, and robotic waste sorting using machine learning (see below). Automating such complicated tasks requires special knowledge to be a profitable investment, according to Søren Peters, CEO of HowToRobot and Gain & Co. “Most businesses use robots to solve immediate needs and are careful with going into experimental projects with a more uncertain outcome,” he said. “The robotic companies that are able to prove the business case in these new areas will be worth watching.” In addition, robotics companies in Finland have managed to find ways to turn…

Found in Robotics News & Content, with a score of 9.98

…pick-and-place tasks and assist with precision operations such as welding. OSARO said its intelligent robots enable goods-to-robot (G2R) use cases, where the greatest gains are yet to be made on the automated warehouse floor. Cobot in action OSARO’s advanced vision software enables robots to see, perceive, grasp, and perform tasks previously done only by humans in e-commerce fulfillment. It allows larger robots—as well as cobots—to manage changes in packaging materials on the fly and reliably handle a vast range of item shapes and SKUs for picking, kitting, and packaging. OSARO vision software is available to integrators and resellers who are…

Found in Robotics News & Content, with a score of 9.94

…internal and external defects and autonomously repair them using welding, milling, and grinding processes. Robel Rail Automation is currently implementing a stationary repair system to test the individual process steps on new and used switches. FANUC robots weld a rail. Source: FANUC European railway networks are already running the first prototype systems, and Robel said it expects the system to be commercially available in two to three years. The Bavarian company added that its system will safely perform continuous maintenance work and help conserve resources. In addition to robots and camera systems, the repair wagon includes integrated scanners, ultrasonic devices,…