Editors’ Picks

Found in Robotics News & Content, with a score of 20.03

…production of metal parts,” said Thomas Bräuer, Bräuer Group welding engineer, “The Meltio Engine integrated with our KUKA robots makes it possible to achieve geometry freedom as well as free us from size constraints.” M600 metal 3D printer designed to make large metal parts Meltio offers a metal 3D printing system that equips industrial applications with a process built around welding wire metal feedstock. The company just presented its latest product, the Meltio M600 metal 3D printer for printing large metal parts, which Meltio said it has tailored to meet the needs of industrial manufacturing with 24/7 production cycles. 3D…

Found in Robotics News & Content, with a score of 9.85

…reach and a repeatability of +/- 0.03 millimeters, about 0.001 inches. The S-Family can be used for automated arc welding, foundry, automotive, and electric vehicle (EV) battery manufacturing processes, food and beverage handling, and general assembly applications. Characterized by their historical red robot design, Comau said the robots also reflect its dedication to making automation more accessible to diverse and non-automotive industries.

Found in Robotics News & Content, with a score of 29.65

…California-based designer and manufacturer of industrial collaborative robots, robotic welding systems and accessories for a wide range of applications, showcased its 7-axis collaborative robots and introduce new technology at Automate 2024 in Chicago. After a recent jobs report found that 2024 will represent the toughest labor market yet, citing a lack of skilled workers, retiring boomer-generation employees and a population decline, Productive sought to demonstrate its offerings will help offset these concerns. Productive Robotics at Automate The OEM debuted and demonstrated its deburr add-on package for CNC applications and its Blaze robotic laser welding system, the latest addition to the…

Found in Robotics News & Content, with a score of 15.00

…overcome labor constraints.” CRX cobots demonstrated palletizing, kitting, and welding Attendees got a chance to experience FANUC’s range of CRX cobots and learn how to program them using hand-guided programming or the Tablet TP interface. A new CRX-25iA food-grade cobot demonstrated collaborative palletizing and depalletizing from an infeed conveyor to two pallets. Designed to operate safely in food processing facilities, the CRX-25iA’s white epoxy coating meets the USDA Incidental Food Contact Requirements. It has an IP67 washdown rating and uses NSF H1 food grade lubricant. The demonstration featured the new PalletTool 3, which enables operators to create and modify unit…

Found in Robotics News & Content, with a score of 15.58

…help to reinforce that.” CL series cobots fitted for welding, finishing, and palletizing Designed and built in Germany, and powered with NEURA Robotics’ robot assistance technology, the CL series can run at a speed of 200 degrees per second with repeatability of +/- 0.02 millimeters, or 0.0008 inches. Payloads and reaches include: 3 kilograms at 590 millimeters, or about 6.6 pounds at 23 inches 5 kilograms at 800 millimeters, or about 11 pounds at 31 inches 8 kilograms at 1300 millimeters, or about 17.6 pounds at 51 inches 10 kilograms at 1000 millimeters, or about 22 pounds at 39 inches…

Found in Robotics News & Content, with a score of 11.98

…and dust resistant mainly for handling but also for welding. And, it’s a bunch of history. We're going back to the red color that has been always the iconic color of Comau robotics. One particular solution we are very proud of is our Mi.RA/OnePicker. We are talking about a system for picking that through a visual system can recognize objects of different dimensions and decide what actions to do. That is also part of our strategy. We are a company with a long heritage in the automotive business. But we are now moving in other sectors. And this is why…

Found in Robotics News & Content, with a score of 14.42

…high-accuracy contact applications, such as machining and friction stir welding, the company said. Powered by OmniCore controllers, ABB said its new robots can achieve motion control with path accuracy down to 0.6 millimeters, or about 0.025 inches, even with multiple robots running at high speeds of up to 1600 millimeters per second, or about 63 inches per second, and moving payloads of up to 620 kilograms, or about 1,350 pounds. Customers can also benefit from an up to 25% reduction in cycle times compared to previous ABB robots. In the automotive industry, the all-new IRB 7710 with the latest OmniCore…

Found in Robotics News & Content, with a score of 11.83

…tailored to human needs. From machine tending to palletizing, welding, and F&B services, the company said it offers a diverse array of ready-to-sell solutions catered to both domestic and global markets. That is why Doosan Robotics’ theme at Automate 2024 is “The Motion Platform Company.” At the show, Doosan Robotics unveiled its latest industrial cobot with new capabilities. The cobot comes with a 30 kg (65 pound) payload. Doosan Robotics booth will feature Dart-Suite, an advanced robot ecosystem designed to redefine the way customers utilize Doosan cobots. The scalable platform elevates cobot capabilities by providing unlimited programmable motions, while ensuring…

Found in Robotics News & Content, with a score of 9.93

…robots are perfect for a wide range of arc welding, handling, food & beverage and general assembly applications, in addition to foundry, automotive and battery manufacturing processes. Further benefits include improved access to small spaces, protected cables to avoid damage and reduce the risk of contamination in sensitive environments, integrated arc and gigabit dressings, and multiple mounting positions to save space without sacrificing performance. Another way Comau is reducing barriers to automation is by making the deployment and management of advanced robotic products increasingly more intuitive. This includes the intelligent programming paradigms found within its robot control software. For example,…

Found in Robotics News & Content, with a score of 12.69

…of perception-guided picking systems, vision-backed handling products, advanced arc welding systems and wearable robotics that help increase operator well-being during heavy and repetitive tasks. All of these offerings address the increasing shortage of skilled labor and the continued growth of automation, which is expected to exceed a growth of +10% CAGR 2022-2030, according to Comau company research. In addition to these technologies, Comau will unveil a new generation of compact robots that specifically address the diverse needs found within automotive and non-automotive applications. To help companies save time, energy and resources, improving the quality of the production processes, Comau’s fully-automated…

Found in Robotics News & Content, with a score of 20.57

…Equity Partners. Acieta expands Angeles’ machine tending, palletizing, and welding offerings across a broader set of end markets including agriculture, foundry and die, welding and fabrication, and construction and building products. Acieta offers standardized and customizable robots Headquartered in Waukesha, WI, Acieta is a full-service industrial automation provider with systems, controls and software engineering capabilities. Since 1983, Acieta has built a large standardized robotics business and installed over 5,500 robots. “Our team is eager to help build what we believe is the country’s most technically capable and experienced automation systems integrator,” said Robby Komljenovic, Acieta CEO. “This combination is designed…

Found in Robotics News & Content, with a score of 12.13

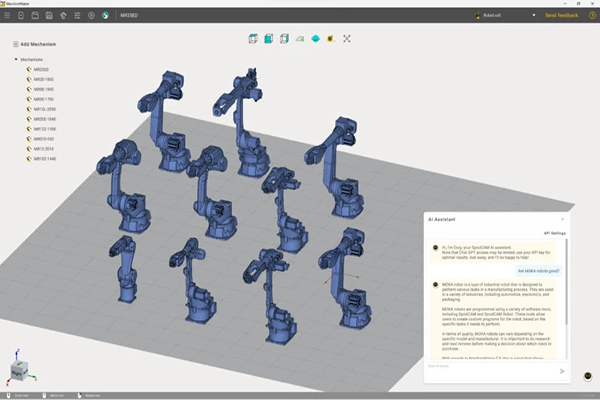

…than 10 series of industrial robot products, including hollow welding robots, handling robots, loading and unloading robots, special robots for die-casting and grinding, stamping robots and others. The SprutCAM X Robot Components Library now includes the following MOKA robot models: MR07S-930, MR08-1840, MR10L-2050, MR10Z-1440, MR12-2010, MR12Z-1550, MR20-1800, MR20E-1840, MR25ED, and MR30-1700. Other enhancements and improvements SprutCAM updated the list of operations for the 2.5D Milling configuration and added Chamfering and 2.5D Contouring operations to the Cutting configuration for robotic machining. Another change in the software update include a change in font size in the CLData Viewer (post processor debugging application)…