Editors’ Picks

Found in Robotics News & Content, with a score of 10.56

…a testament to the advancements being made in robotic precision and are an example of how robots are being used for more and more applications. More robot chefs expected There’s a novelty seeing a robot prepare a food and beverage, but in many instances there are also human workers involved, whether that be directly interacting with customers or troubleshooting the robot where an error occurs. The food and beverage robotic space is estimated to reach $4 billion by 2026, with an annual growth of 13.1%, according to Markets and Markets. While much of that growth will come from the packaging…

Found in Robotics News & Content, with a score of 10.52

Renishaw, a precision engineering and manufacturing technologies company, worked with Michigan-based Cobra Aeroto to improve the engine manufacturer’s design processes for aircraft and motorcycle engines. After completing the project with Renishaw, Cobra Aero invested in an AM 400 system to increase its in-house additive manufacturing (AM) capabilities. To optimize the design of its engine cylinders and to gain expertise in AM, Cobra Aero visited a Renishaw Additive Manufacturing Solutions Center. There they collaborated with Renishaw engineers to discover how AM could improve the design of a cylinder for an unmanned aerial vehicle (UAV). “Investing in AM allows us to develop…

Found in Robotics News & Content, with a score of 10.51

…Mitsubishi Electric industrial robots are equipped with speed and precision to meet the demands of today’s manufacturing applications. The newest RV-35/50/80FR series of robots are designed to allow for an expanded work envelope and increased opportunity through its increased payload and reach compared to prior series. Heavy payload options with new Mitsubishi series The RV-34/50/80FR series has a maximum reach of 2100mm (82 inches), and a maximum payload of 80kg (176 lbs.), making them options for palletizing and machine-tending applications. This series of robots connect to a wide range of factory automation equipment to seamlessly integrate robot functionality with IT…

Found in Robotics News & Content, with a score of 10.49

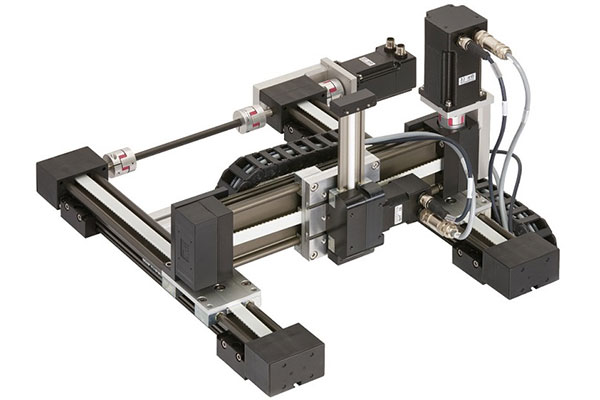

…automation and repetitive material handling. You can adjust their precision, speed, stroke length and size, and add almost any type of linear actuator with any variety of drive mechanisms. Gantries can handle larger payloads and much longer stroke lengths since the Y axis is supported. 2. Delta Robot Delta robots, also called parallel or spider robots, consist of three arms and a single base. The base is mounted above the work area while the arms move at high speeds (i.e., 200 picks per minute) with the help of motors on each axis (Process Solutions Inc). However, the delta's payload capacity…

Found in Robotics News & Content, with a score of 10.43

…is “applying the next generation of robots to intelligent precision assembly and medical treatment [tasks] that can only be accomplished by human beings right now. With the support of our reputable investors and customers, we are confident to push robotics into a new era.” Founded in 2018, Agile Robots AG said it has know-how robotics software and hardware. The company has headquarters in both Munich and Beijing. With German Aerospace Centre (DLR) as its technical backbone, Agile Robots said it combines artificial intelligence and robotics innovation to expand automation to more fields. Not only is DLR is not only the…

Found in Robotics News & Content, with a score of 10.43

…machinery and service robots. Perception Engine v2.0 brings greater precision and visibility RGo said it develops disruptive AI-powered technology for autonomous mobile robots, allowing them to achieve 3D, human-level perception. It noted that its Perception Engine gives mobile robots the ability to understand complex surroundings and operate autonomously like humans. It integrates with mobile robotic systems to deliver centimeter-scale position accuracy in any environment. The engine surpasses the cost and performance capabilities of traditional LiDAR and reflector-based positioning technologies while meeting the high robustness standards of industrial systems, the company claimed. In Q2 2023, RGo will release the next iteration…

Found in Robotics News & Content, with a score of 10.40

…much longer continuous runs in series production operations of precision functional parts. Beyond substantially extended useful life, the Everlast Membrane exhibits consistent optical transmittance, so the 1000th produced part is identical to the first, and improves the surface finish and dimensional accuracy of all printed parts across the entire material portfolio. The Everlast Membrane is fully compatible with NXE400 workflows and printing parameters, offering dynamic performance monitoring of the membrane with predictive usability feedback. “3D print manufacturers seek every possible advantage to keep their workflows moving as fast and efficiently as possible while maintaining consistent production standards,” says Michele Marchesan,…

Found in Robotics News & Content, with a score of 10.35

…at booth 1231. More details about each demo Compact, High-Precision SCARA Robots – The Epson GX4 and GX8 SCARA robots offer high throughput, smooth motion control, and heavy payloads with advanced Epson GYROPLUS Technology. Offering multiple arm configurations, a 250 to 350 mm (98-18 in.) reach with the GX4 and a 450-650 mm reach with the GX8, the robots can achieve ultra-high precision in applications such as assembly, pick-and-place, and intricate small-parts handling. The GX4 can handle payloads up to 4 kg (8 lb.) and the GX8 can handle up to 8 kg (17 lb.), both from a small form…

Found in Robotics News & Content, with a score of 10.35

…speed, importance As end-of-arm tooling [EOAT] technologies improve in precision and more industries look to automation, gripper makers have kept busy. Software advances are big driver, as user interfaces have become easier to use. On the hardware side, there are new engineering feats such as the introduction of seven-axis collaborative robots and new grippers outfitted with force sensors. Customers are always asking for more precision, speed, and flexibility, Green said. Getting customers the systems they desire takes a combination of many different types of technologies. “You really need to marry a number of different technologies into an end-of-arm tool to…

Found in Robotics News & Content, with a score of 10.30

…environments and applications. The new SCARA units feature ultra-high precision, flexibility, and integrated SafeSense™ technology to help maximize productivity for the most challenging applications. At the Epson display booth, attendees will have the opportunity to experience live product demonstrations of Epson’s 6-axis robots, the IntelliFlex™ Parts Feeding System, and RC+® industrial automation development software, and why they are ideal solutions for the medical device, electronics and consumer packaged goods markets. Epson VT6L is a 6-axis robot used in manufacturing. Source: Epson An Epson expert will also present a technical session on the company’s advancements in parts feeding with a review…

Found in Robotics News & Content, with a score of 10.23

…productivity. With SICK’s patented outdoor-safeHDDM™ technology, you can get high-precision measurement data for reliable use, even in challenging weather conditions. This data can be used for navigation and relative positioning tasks. Serva Transport Systems partnered with SICK to create autonomous transport robots for the factory of the future. EVE is an automated solution for production processes that uses the outdoorScan3 to go indoors and outdoors. Related White Papers Taking AGV Safety Outdoors with SICK’s New Safety Laser Scanner With a growing need for continuous improvement and automation, AGVs are being rapidly adopted in many industries. Whether used for pallet handling,…

Found in Robotics News & Content, with a score of 10.07

…with which the giraffe gazelle stands and its ultimate precision in gathering the best-tasting leaves from trees,” said euroTECH. “The eT-Litocran700 offers unprecedented 3D fine-tuned control for fast, low-labor installation of windows as well as glass and facade elements,” the company said. euroTECH develops and produces customer-specific vacuum systems and components for automated handling tasks. It said users can adjust its modular construction system to meet their requirements. The company added that they can quickly install spare parts for cost savings. eT-Litocran700 offers flexibility euroTECH's eT-Litocran700 combines a 3D head on a robotic arm with a vacuum lifting device. The…