Editors’ Picks

Found in Robotics News & Content, with a score of 4.12

…We've found strategic ways to use cellphone sensors and plastic lens tech. It's only in the past 10 years that we could get force and position sensing in the body in real time.” “We're also developing advancements with AI, which will hugely expand the capability of surgeons to use their intelligence in planning procedures rather than in monotonous tasks,” he added. “We're looking at allowing systems to do more execution, and we're designing our system with the hooks to do this.” “Sensors can map the abdomen in real time,” Sachs said. “We're not building a car, but with lidar and…

Found in Robotics News & Content, with a score of 4.27

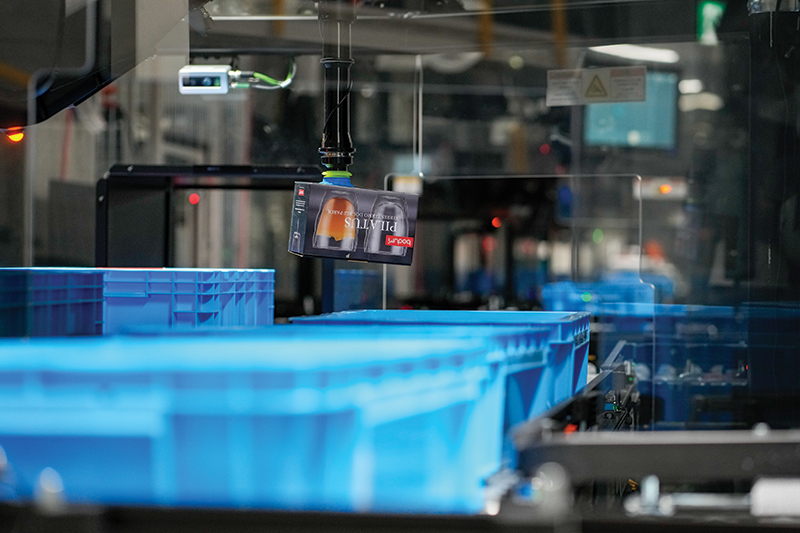

…combining systems and packing machines. It uses almost no plastic cushioning material in packing. This leads to a reduction of packing materials and a reduction in carbon dioxide emissions. The third leg, which is critical to the Japanese consumer, is quality, or the appearance of the package that is handed off to the consumer, including the transport package. In the U.S., we tolerate the occasional ding and dent in packaging, even consumer packaging, if the product we ordered looks great and works as expected when we remove it and put it to use. That is not the case in Japan.…

Found in Robotics News & Content, with a score of 8.56

…assemble components for numerous products. Without operators, these simple plastic and glass parts cannot be made. And without those components, entire factories sit idle, said Rapid Robotics. “We hear a lot about the semiconductor shortage, but that’s just the tip of the iceberg,” said Jordan Kretchmer, CEO of Rapid Robotics. “Contract manufacturers can’t produce gaskets, vials, labels—you name it. I’ve seen cases where the inability to produce a single piece of U-shaped black plastic brought an entire auto line to a halt.” Rapid Machine Operator ready to go Rapid Robotics claimed that its Rapid Machine Operator (RMO) is the world's…

Found in Robotics News & Content, with a score of 4.58

…demonstrating that 3D printing isn't just for widgets and plastic parts anymore. It can entail complex materials, large-scale fabrication, and be used with robotics to produce things that were previously unthinkable. In this case, a wind turbine blade just shy short of a football field in length. The bloom of new ecosystems? The combination of AM and robotics exemplifies the new bloom of ecosystems that are budding from industrial landscapes. When one disruptive technology combines with another, they can result in entirely new developments and once-impossible constructs. And it’s not just the possibilities that such an ecosystem creates; it’s also…

Found in Robotics News & Content, with a score of 5.42

…also enables us to use certain materials, such as plastics or fabrics, to make our system more flexible, lightweight, and cost-effective. It's only a few thousand dollars, compared with tens or hundreds of thousands.” “These materials also enable us to rapidly prototype and innovate, unlike traditional prototyping and 3D printing, which are time-consuming and expensive,” he added. “This enables us to tailor the system to human anatomy and more easily scale up.” “The knee actuator transmits torque for movement,” he explained. “One area of customization is optimizing fit for comfort. We can take a user's measurements for the thigh and…

Found in Robotics News & Content, with a score of 5.08

…is a big application,” Charles added. “We've seen facilities where products come in, and workers need to take away plastic packing or broken-down cardboard boxes. Bins already have a bar that we could grab on to.” “With solid mechanical solutions ranging from 100 to 1,000 kg., that covers a lot of applications,” he said of the MiR250 Hook. “Our growth moving forward will be software-related. We make continuous updates, and we're focused on our new AI cameras and ease of deployment.”

Found in Robotics News & Content, with a score of 6.03

…and technical glass applications; and high-quality chrome-plated and painted plastic components for the automotive and commercial truck industries. Wichita, Kansas-based Koch is one of the largest private companies in the U.S., with estimated annual revenues as high as $115 billion, according to Forbes. It owns a diverse group of companies involved in chemicals, consumer products, electronics, automotive components, and investments, among other industries. Koch recently invested in Percepto for autonomous inspection of industrial sites. Autonomous mobile robots on the rise Guardian Industries and Koch are not the only companies that want to optimize internal transportation flows, according to Mobile Industrial…

Found in Robotics News & Content, with a score of 9.01

…variety of types of cargo. Manufacturers in automotive, aerospace, medical, alternative energy, fabricated metal, industrial machinery, and rubber and plastics space have also used AMT's systems.

Found in Robotics News & Content, with a score of 5.87

…are optimized for high-throughput manufacturing of functional, complex 3D plastic and rubber parts. Adaptive3D's flagship resin is Elastic ToughRubber 90, a durable, printable photopolymer elastomer. The company said it serves high-throughput manufacturing, while maintaining low cost of production and superior material performance. Adaptive3D has received strategic capital from leading materials companies including Covestro, Arkema Group, West Pharmaceuticals, Applied Ventures, and Royal DSM. It noted that Desktop Metal's scale and channel network provide “a massive opportunity” for it to expand. “We are thrilled to partner with Desktop Metal to enable additive manufacturing through our differentiated materials,” said Dr. Walter Voit, founder…

Found in Robotics News & Content, with a score of 8.54

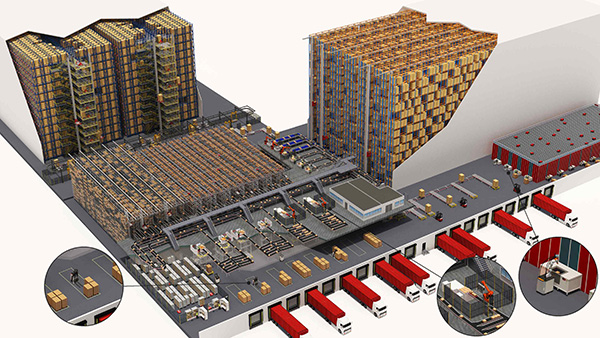

…for the transportation of raw materials such as paper, plastic, rubber, steel, and metal. AMRs move around the facility autonomously. They do so using technologies such as lidar, machine learning, and the cloud, as well as vision-based navigation. Thanks to their flexibility, they are often used for repetitive tasks that were previously carried out by human workers. Certain mobile robots can also safely collaborate with humans for goods-to-person applications. Types of warehouse tasks being automated There are several categories of tasks for robots to handle. The first is robots used in transporting goods, from automated lift trucks to heavy load…

Found in Robotics News & Content, with a score of 7.86

…a number of industries including consumer electronics, auto components, plastics, food and beverage, lab automation, appliances, and medical device manufacturing.” FANUC widens range of SCARA robots FANUC America said its family of four-axis SCARA robots has grown to include the SR-3iA, SR-6iA, SR-12iA, and new SR-20iA models, with 3kg, 6kg, 12kg and 20kg (6.6 to 44 lb.) payload capacities, respectively. They have a reach of 400 to 1,100mm (15.7 to 43.3 in.). The small SR-3iA and SR-6iA SCARAs have a compact footprint and space-saving design for maximum efficiency, according to the company. In addition, the SR-3iA/H and SR-6iA/H are three-axis…

Found in Robotics News & Content, with a score of 3.23

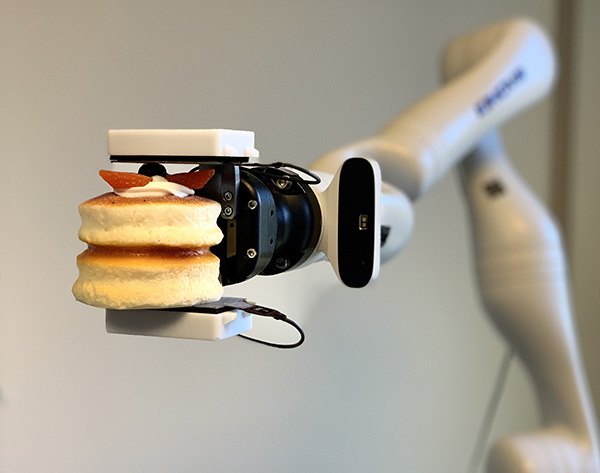

…known affordances and can automatically adjust for steel versus plastic.” “The only way for robots to move forward is to build libraries of skills and determine what the function is like,” said Nikovski. “To achieve one-shot learning is a holy grail. There are technologies that allow learning a single trajectory that allow for starting state and goal location with simple dynamic moves and primitives.” Source: MERL MERL trains robots with in-house data Part of the challenge of making cobots more dexterous is the amount of data to process from sensors or needed for training. MERL is using its own machine…