Editors’ Picks

Found in Robotics News & Content, with a score of 55.84

As additive technologies, materials, and processes mature, so does the argument for using additive manufacturing (AM) to make production parts—let go of traditional manufacturing constraints and embrace a new mindset that explores additive manufacturing as a serious means of production. Additive Manufacturing vs. Injection Molding The additive technologies most commonly used for production of plastic parts include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). The break-even point of AM compared to injection molding (IM) was once a few hundred parts but is now pushing into the thousands with trends showing the cut-off point even…

Found in Robotics Companies & Businesses, with a score of 54.65

Sciaky’s Electron Beam Additive Manufacturing (EBAM) is a one-of-a-kind 3D printing technology that delivers on the key benefits mentioned above and excels at producing large-scale, high-value metal parts. Sciaky’s 3D Printing Facility, our EBAM services team and capabilities have grown exponentially, and so has interest from companies who are determined to explore additive manufacturing’s advantages over traditional manufacturing and prototyping processes.

Found in Robotics Companies & Businesses, with a score of 54.00

…designers and engineers make the unmakeable. Experts Focused on Accelerated Prototype Fabrication & Low- to High-Volume Production Part Services Additive, Traditional, & Hybrid Manufacturing Expertise with an Industry-Leading Advantage of Agility 3D Printing, Additive Manufacturing, CNC Machining, Urethane Casting, Tooling, & Injection Molding We are uniquely blending additive technologies and materials with legacy manufacturing methods so companies can go from concept to prototype to manufacturing in a way that wasn’t previously possible.

Found in Robotics News & Content, with a score of 53.85

…of the leading machine manufacturers to validate their new additive cycles. The DP Technology teams announce the first commercial version of ESPRIT that includes additive direct energy deposition (DED) cycles. ESPRIT’s additive capabilities include the same intuitive user interface that users expect from the software. The product release includes three-, four- and five-axis DED support. Combined with the subtractive processes and embedded into a single software, DP Technology brings a spectrum of support to hybrid manufacturing. ESPRIT’s additive DED cycles include additive simulation and verification, as well as global support from ESPRIT’s technical teams. DP Technology validated their post-processor through…

Found in Robotics Companies & Businesses, with a score of 53.09

We enable our customers to produce innovative and high quality products based on industrial 3D printing technologies. EOS is the global technology and quality leader for high-end solutions in the field of additive manufacturing (AM). Founded in 1989, we are a pioneer and world leader in the field of Direct Metal Laser Sintering (DMLS) and provider of highly productive Additive Manufacturing Systems for plastic materials.

Found in Robotics News & Content, with a score of 50.55

…the ESPRIT CAM system, is enhancing its support of additive manufacturing processes with a new software specifically for the powder bed fusion market. Called ESPRIT Additive for Powder Bed, the program comes as an add-in application for SolidWorks, a computer-aided design (CAD) program. ESPRIT Additive for Powder Bed Fusion is compatible with any file supported by SolidWorks. One standout feature of the new software is the patented Part-to-Build When preparing a part for manufacturing, the program automatically assigns exposure strategies based on simple inputs from the user. ESPRIT Additive for Powder Bed Fusion also introduces a slicer that offers accuracy…

Found in Robotics News & Content, with a score of 49.78

EOS and AMFG, provider of MES software for additive manufacturing, have announced a partnership enabling direct streaming to and connectivity with EOS machines. The lack of connectivity across the additive manufacturing workflow remains one of the biggest barriers to adoption. Through their partnership, EOS and AMFG aim to remove this barrier and establish a fully connected and automated additive manufacturing workflow. Customers of EOS machines will be able to manage their entire additive manufacturing operations with AMFG’s Manufacturing Execution System (MES), while simultaneously connecting directly with their machines through the software platform. “EOS has always been at the forefront of…

Found in Robotics Companies & Businesses, with a score of 47.65

Stratasys Ltd. (Nasdaq:SSYS), headquartered in Minneapolis, Minnesota and Rehovot, Israel, is a leading global provider of 3D printing and additive manufacturing solutions. The company’s patented FDM®, PolyJet™, and WDM™ 3D Printing technologies produce prototypes and manufactured goods directly from 3D CAD files or other 3D content. Systems include 3D printers for idea development, prototyping and direct digital manufacturing. Stratasys subsidiaries include MakerBot and Solidscape, and the company operates a digital-manufacturing service comprising RedEye, Harvest Technologies and Solid Concepts. Stratasys has more than 2,500 employees, holds over 600 granted or pending additive manufacturing patents globally, and has received more than 25…

Found in Robotics News & Content, with a score of 47.22

…Aerospace CTO Russ Dunn will officially open the latest Additive Industries Process and Application Centre close to Bristol in the UK on March 12, 2020. This center is part of the global network of Additive Industries Competence Centres, also located in Eindhoven, Los Angeles and Singapore, each having their own specialty in different aspects of industrial additive manufacturing. The UK & Ireland Process and Application Centre’s core competence will be new materials and process development. The center is located on the historic Filton Aerospace Park, directly in the middle of the growing additive manufacturing hub that is there. Filton has…

Found in Robotics News & Content, with a score of 44.91

…announces a strategic alliance with Auburn University to accelerate additive manufacturing research and test development. Auburn University is home to the National Center for Additive Manufacturing Excellence (NCAME), which is a founding partner of the ASTM International Additive Manufacturing Center of Excellence (AM CoE). As part of the alliance agreement with the university, MTS will supply test equipment to Auburn's NCAME mechanical testing lab and share expertise to advance mechanical testing methods for additively manufactured materials and components. Auburn University's NCAME and MTS are working together to identify the mechanical testing advancements necessary for further adoption of additive technology. “MTS'…

Found in Robotics News & Content, with a score of 44.86

Stratasys Direct Manufacturing is expanding its additive metals offering with the addition of VELO3D’s Sapphire 3D print system and Flow software. The Sapphire laser fusion metal additive manufacturing system allows for printing of complex part geometries with in-situ metrology, closed-loop control, and low-to-no support structures. The solution’s built-in tools include support generation, simulated print predictions, per-surface process application, slice composer and process review. This functionality allows for 3D printed production of complex metal components with more quality control, the company reports. “The Sapphire system from VELO3D is an important part of advancing our capabilities to include using additive metals in…

Found in Robotics News & Content, with a score of 44.69

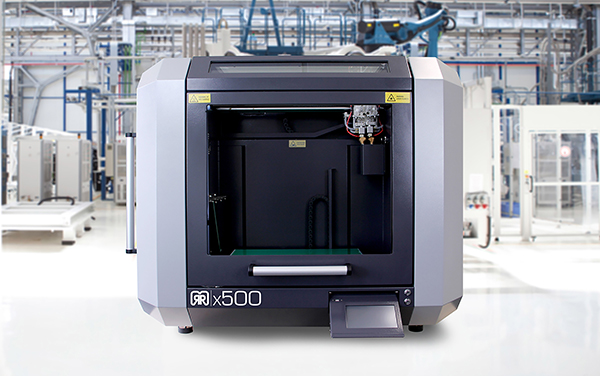

In the automotive industry, additive manufacturing has become a high priority, according to German RepRap. Different car parts and prototypes are developed with the help of additive manufacturing and thus a faster achievement of the series maturity is possible. In prototyping, fixtures, production and assembly aids, the technology has become the standard and allows the use in end products through the use of various flexible materials. German RepRap has been supplying the BMW Group for several years. The German RepRap x500 is used, for example, for the production of prototypes in the field of predevelopment. One of the most decisive…